CNC vertical lathe LCK1000

CNC vertical lathe Product description::

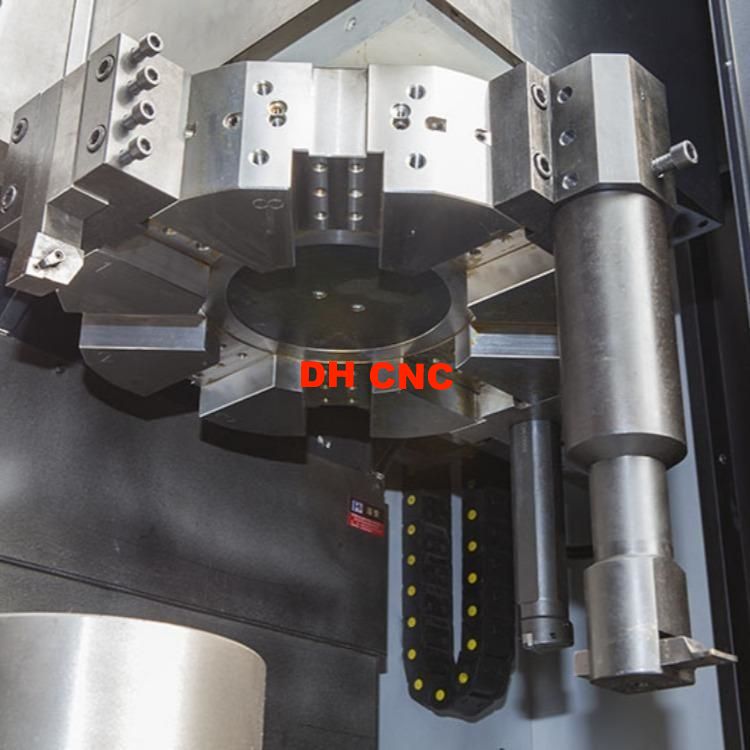

LCK Vertical CNC lathe is an excellent product designed and produced by our company for many years on the basis of absorbing the advanced technology of similar CNC vertical lathe at home and abroad. This series of CNC vertical lathe is economical and efficient, and is the first choice for processing complex disk parts in automobile, industry and other kinds of machinery industries. This series of CNC vertical lathe can process all kinds of short shaft and disc parts, can turn all kinds of thread, arc, and rotary body inside and outside surface, end face, groove. It is suitable for parts with large batch, high machining precision and high dimensional consistency. This series of CNC vertical lathe is widely used in automobile industry at home and abroad, and is a kind of high quality, high precision, low cost and high efficiency CNC vertical lathe.

Description

CNC vertical lathe LCK1000

Product description of CNC vertical lathe:

LCK vertical CNC lathe is an excellent product designed and produced by our company after years of careful design based on the advanced technology of similar CNC vertical lathes at home and abroad. This series of CNC vertical lathes is economical and efficient, and is the preferred equipment for processing complex disc-shaped parts in the automotive, industrial and other mechanical industries. This series of CNC vertical lathes can process various short shafts and disc-shaped parts, and can turn various threads, arcs, and internal and external surfaces, end faces, and groove surfaces of rotating bodies. It is suitable for processing parts with large batches, high processing accuracy, and high dimensional consistency requirements. This series of CNC vertical lathes are widely used in the automotive industry at home and abroad. It is a high-quality, high-precision, low-cost, and high-efficiency CNC vertical lathe.

Compared with previous similar CNC vertical lathes, it has the following advantages:

Important parameters such as the maximum processing diameter and two-axis rapid moving speed of CNC vertical lathes are close to or greater than similar foreign CNC vertical lathes.

The CNC vertical lathe has a compact structure, a small footprint, a reasonable layout of various functional components, and is easy to operate and maintain.

CNC vertical lathes are inexpensive and cost-effective. They are suitable for small and medium-sized enterprises to purchase in single or batch quantities, effectively reducing corporate procurement and operating costs.

| 项 目 t | LCK550 | LCK650 | LCK850 | LCK1000 | LCK1200 |

|---|---|---|---|---|---|

| 最大回转直径(mm) Maximum turning dia. | 600 | 700 | 900 | 1050 | 1200 |

| 最大切削直径(mm) Maximum cutting diameter | 500 | 650 | 850 | 1000 | 1200 |

| 主轴接口 Spindle interface | A2-8 | A2-11 | A2-11 | A2-15 | A2-15 |

| 主轴转速(r/min) Spindle speed(r/min) | 50-2000 | 50-2000 | 50-1200 | 30-1000 | 30-1000 |

| 切削进给速度(mm/min) cutting feed rate(mm/min) | 1-300 | 1-300 | 1-300 | 1-200 | 1-200 |

| 刀架垂直行程(mm) Vertical travel of knife holder | 550 | 800 | 800 | 800/1000 | 1000 |

| 刀架水平行程(mm) Horizontal trave of knife holder | 400 | 480 | 480 | 550 | 700 |

| X轴快移速度(mm/min) x aixs fast moving speed(mm/min) | 8000 | 8000 | 8000 | 8000 | 8000 |

| z轴快移速度(mm/min) z aixs fast moving speed(mm/min) | / | / | 1 | / | 1 |

| 主电机功率(KW) Main motor power | 18.5KW | 18.5KW | 22kw | 22KW | 30KW |

| 最大工件重量(吨) maximum workpiece weight | 1 | 1 | 1 | 1 | 1 |

| 刀架形式(mm) Knife holder form | Optional | Optional | Optional | Optional | Optional |

| 刀杆尺寸(mm/mm) Knife bar size | 25×25 | 32×32 | 40×40 | 40×40 | 40×40 |

| 机床外形尺寸(mm) overall dimension | 1800×1960 ×2850 | 2000×2000 ×3250 | 2150×2050 ×3300 | 2300×2150 ×3350 | 2400×2350 ×3400 |

| 机床重量约(吨) Machine weight | 4 | 6.3 | 9 | 11 | 12 |

| X/Z轴定位精度(mm) x/z aixs positioning accuracy | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 |