CNC Gantry Machining Center GMC2013

The CNC gantry machining center has high rigidity and reliable structural design, so it not only has the ability of strong cutting, but also can meet the processing of precision parts. The product is suitable for metallurgy, railways, heavy machinery, ships, power generation, automobiles, aerospace, printing, molds and other industries. It can work normally and continuously under the environmental conditions specified in the technical documents with stable precision. It is mainly used for the processing of heavy and super heavy parts, especially for CNC processing of various planes, curved surfaces, spatial curved surfaces and holes of ferrous and non-ferrous metals with large weight and long workpiece length. It is widely used in the rough and fine processing of various complex parts such as plates, boxes and racks in the machinery manufacturing industry. The machine tool can complete curved surface processing and rigid tapping, and the addition of an accessory milling head can complete the processing requirements of pentahedrons. And according to the customer’s processing technology requirements, an accessory milling head can be added, and according to the processing technology of the workpiece, a pentahedron can be processed in one clamping.

Description

CNC Gantry Machining Center GMC2013

Main structural features and characteristics of the machine tool:

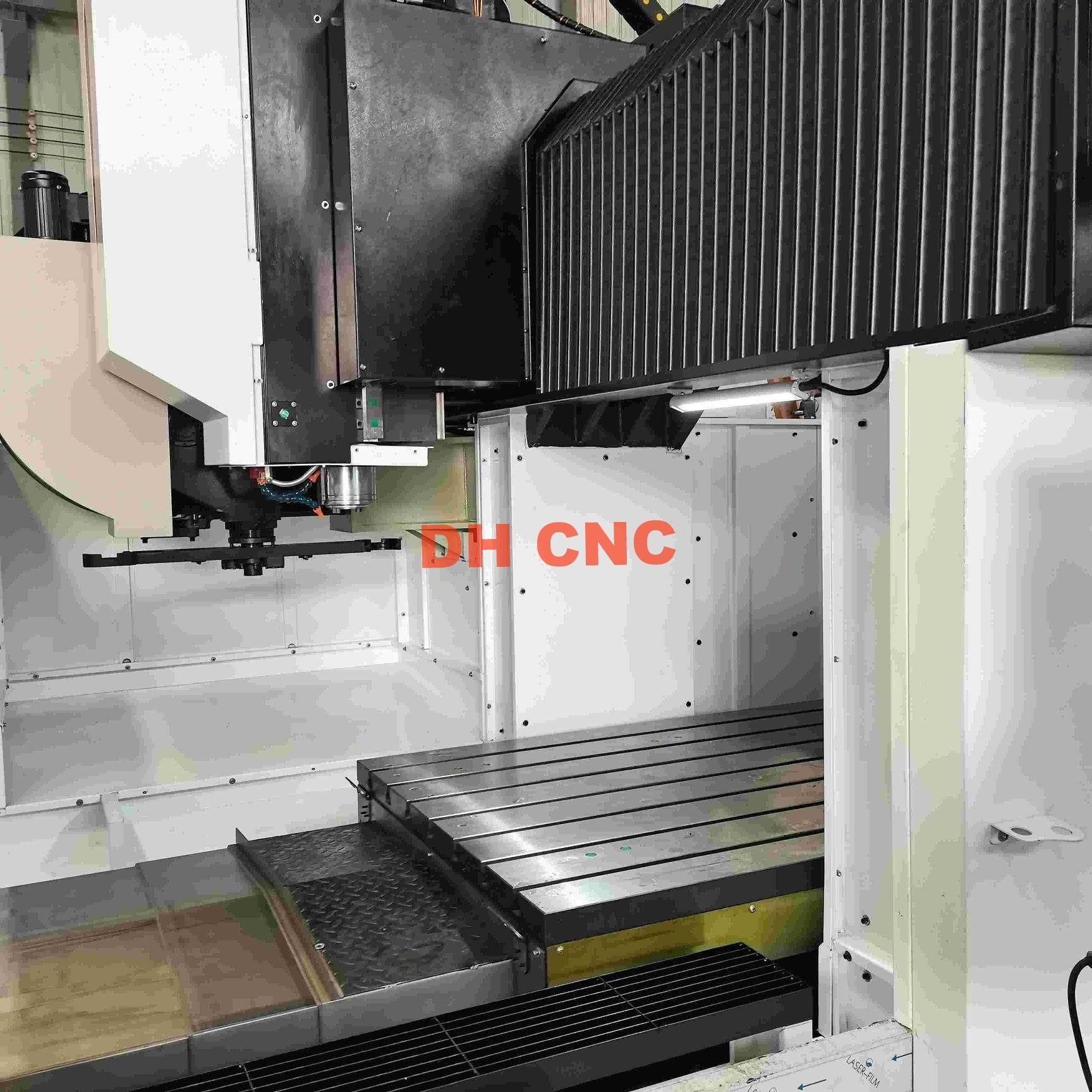

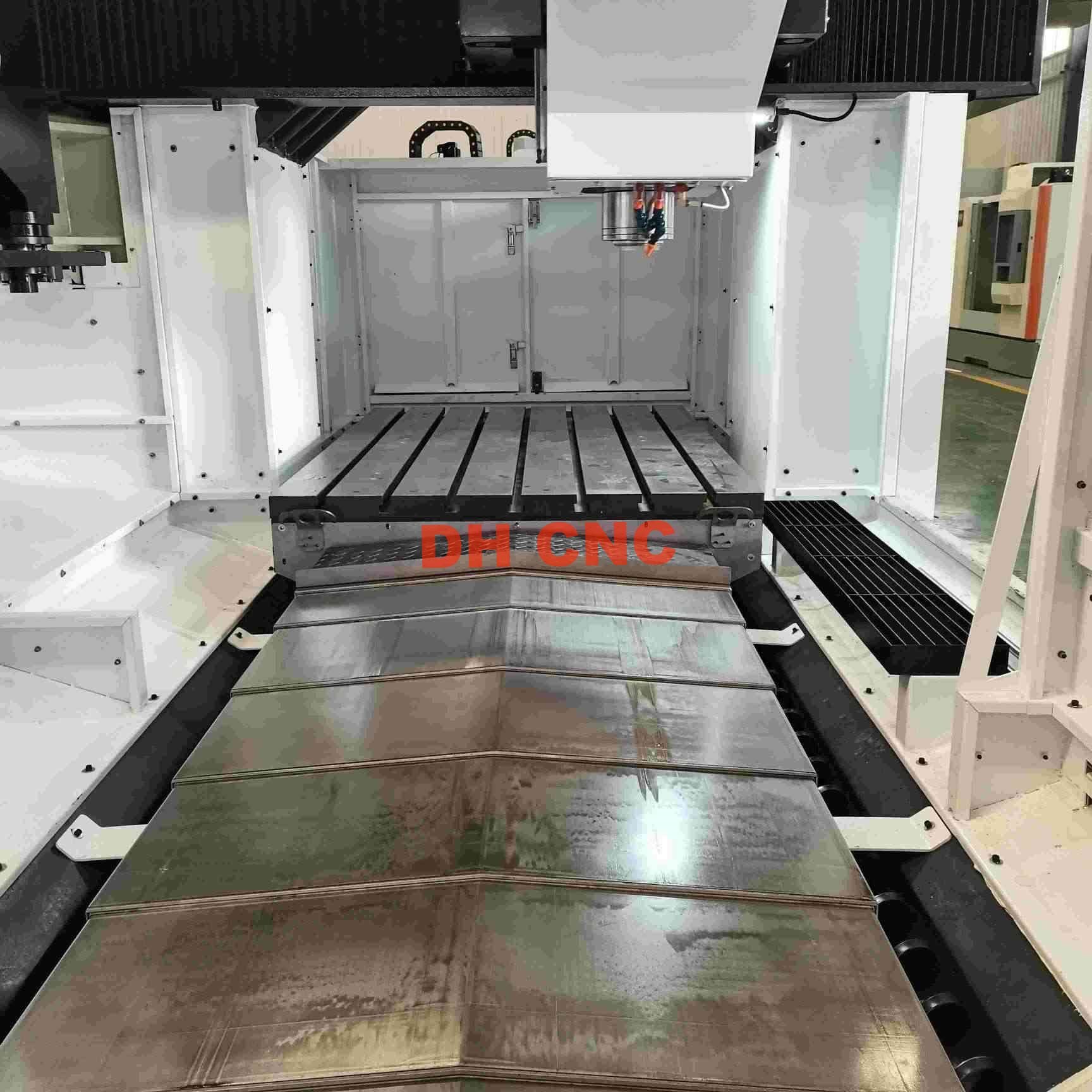

The basic structure of the GMC02016 CNC gantry machining center is a beam-fixed gantry frame, a fixed bed, a movable worktable, a milling head slide that moves left and right along the beam guide rail, and a milling head slide that moves up and down along the slide rail to achieve three-axis linkage.

1. This machine tool consists of a bed, a worktable, a column, a beam, a slide, a ram, a lubrication system, a cooling system, a pneumatic system, etc. The bed adopts a box-type structure design and is supported by delicate ribs. The bed, column, beam, worktable, etc. are all made of high-quality cast iron parts, and are treated with aging to eliminate stress, with good rigidity, stable precision, and durability.

2. The worktable adopts heavy-duty linear rolling guides with good load-bearing performance and good dynamic performance. The XYZ axis drive adopts direct connection with an AC servo motor, and the XYZ axis guide pair adopts a linear rolling guide.

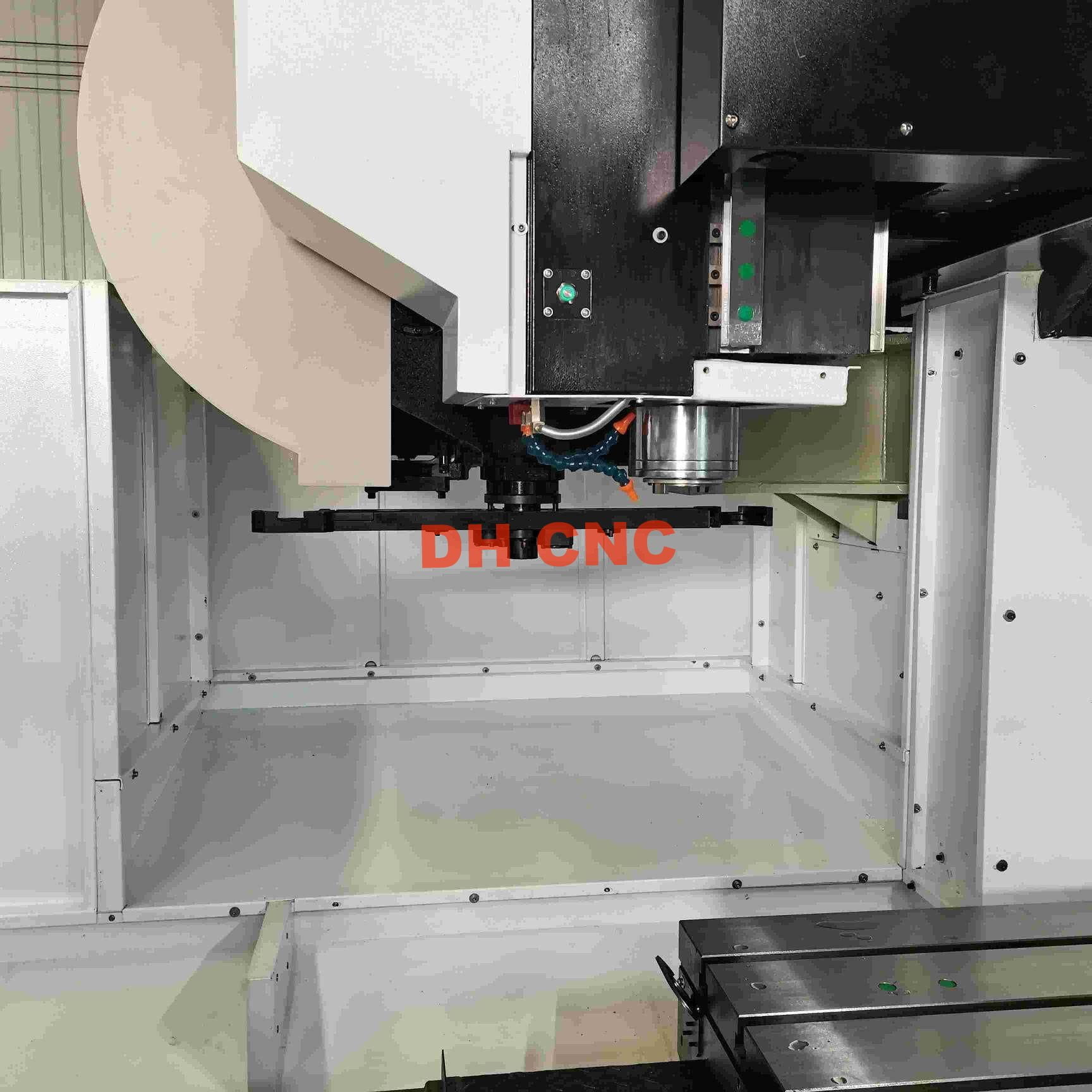

3. The slide adopts a “labyrinth” design with good rigidity, which can prevent impurities from entering the spindle. With the central symmetrical Z-axis spindle head design, the Z-axis screw and the spindle are located in the center of the spindle head, which will not produce uneven vibration and displacement due to offset, reduce cutting torque, and reduce vibration during heavy cutting.

4. The ultra-wide door design and ultra-long stroke design are suitable for the processing of large workpieces, and the maximum load-bearing capacity of the workbench can reach 4000kg.

5. The X/Y/Z-axis screws all use high-precision ball screws and optimize the preload.

6. The Z-axis of the machine tool adopts a ball screw double power-off brake device, and the braking effect is safe and reliable.

7. The milling head of the machine tool is equipped with a spindle rotation detection system, which can realize the automatic positioning and tapping functions of the spindle.

8. All moving parts of this equipment have a complete centralized lubrication system, which can realize timed, quantitative automatic and manual lubrication, and can detect and alarm.

9. The equipment should have an automatic cooling device and a coolant recycling device. A cooling system should be set up to cool the workpiece externally. The cooling system consists of a water tank, a water pump motor, a filter, a pipeline, a valve, and related hardware necessary for external cooling of the spindle head. A cleaning water gun is standardly configured.

10. Pneumatic: The compressed air of this machine tool is mainly used for cleaning and blowing the tool holder. The pneumatic device should comply with relevant pneumatic standards such as GB/T6576.

| Specifications | Units | GMC2013 |

|---|---|---|

| Table size | mm | 2000x1000 |

| X axis travel | mm | 2000 |

| Y axis travel | mm | 1300 |

| Z axis travel | mm | 600 |

| Distance between spindle nose and worktable surface | mm | 140-740 |

| Columns distance | mm | 1100mm |

| Distance between table and cross beam | mm | 1300 |

| T slot(number-width-pitch) | mm | 7-22x150 |

| Max. spindle speed | rpm | 6000 |

| Spindle taper | mm | BT40 (Optional:BT50 ) |

| Main motor power | kw | 15/18.5 |

| Main motor | NM | 143 |

| Guide rail type | RGW/H 55 Linear guide | |

| X/Y/Z rapid traverse speed | m/min | 12/10/2012 |

| Max.table load | Kg | 4000 |

| Distance from table to floor | mm | Around 800 |

| Cutting feed speed | mm/min | 1-10000 |

| XYZ Axis Positioning accuracy | mm | ±0.02/0.02/0.015 |

| XYZ Axis Repeat positioning accuracy | mm | 0.015/0.015/0.01 |

| Tool magazine | Arm 24 | |

| Max. tool diameter | mm | φ78 (Adjacent)/ φ120(Apart) |

| Optional: φ112 (Adjacent)/ φ200(Apart) | ||

| Max.tool weight | kg | 18 |

| PULL | P50T-1(45°) | |

| Tool change time | sec | 2.5 |

| Machine weight | kg | 18000 |

| Overall dimension | mm | 6000x3500x4200 |