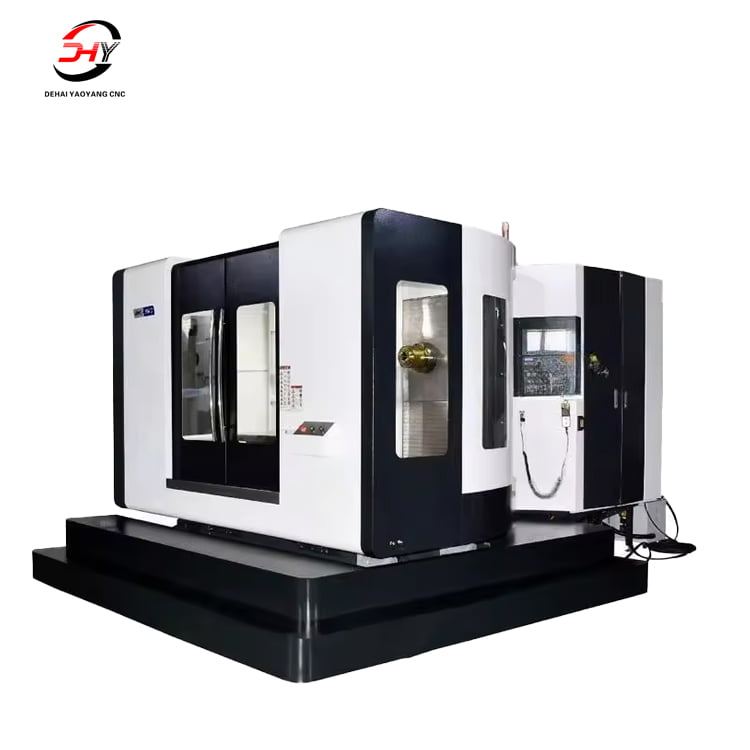

Horizontal Machining Center HMC500

Product description:

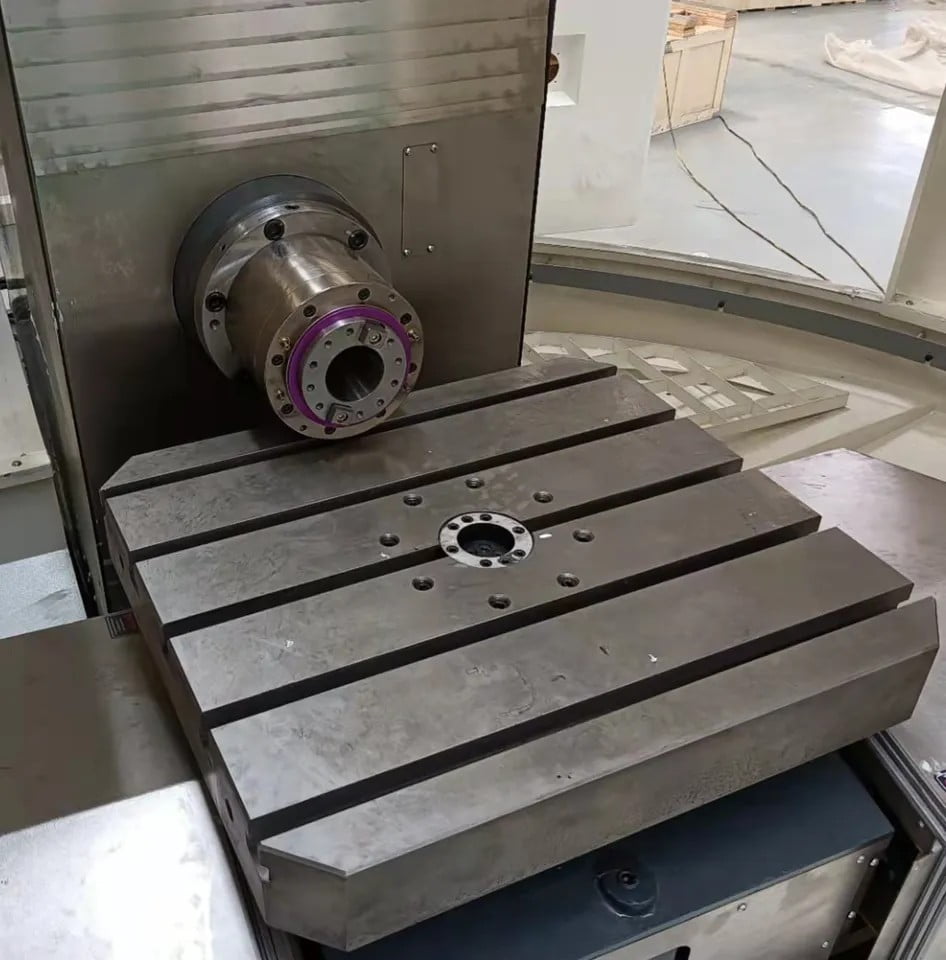

HMC series precision horizontal machining center adopts positive T-shaped structure, integral base, large span double wall column, three-axis heavy-duty roller guide rail, and high structural strength of the whole machine. The spindle is directly connected with forced cooling, and the machine tool accuracy is stable. Equipped with a double-pallet automatic workpiece exchange system, it is suitable for batch multi-faceted processing of parts such as boxes, discs, shells, machine bases, etc., and is also suitable for fine processing of various molds.

Description

Horizontal Machining Center HMC500

Features:

1) The machine tool adopts a positive T-shaped structure, a high-strength integral cast iron base, and a large-span staircase layout for the columns, with excellent precision retention.

2) The whole machine adopts a high-rigidity design, and the main structure has undergone error strain and finite element analysis.

3) The three axes adopt heavy-duty roller linear guides, with good dynamic response performance and high precision retention. Ensure high speed, rigidity, and high rigidity of processing movement.

4) High-speed transmission box self-weight balance system, good high-speed stability.

5) Hydraulic chain tool magazine, large load-bearing capacity and high stability.

6) Double workpiece automatic exchange system to improve processing efficiency.

7) Built-in double spiral post-cooling film arrangement device, large film arrangement capacity and compact structure; adopts water tank separation type, which is convenient for movement and cleaning.

Applicable industries:

Applicable to automobile, mold, communication, medical equipment, instrumentation and other industries.

| Model | HMC500 | HMC630 | HMC800 |

|---|---|---|---|

| Worktable size(LxW) | 500x500mm | 630x630mm | 800x800mm |

| Tslot | 18mmx5x100mm | 22mmx5x125mm | 22mmx5x125mm |

| Worktable inndexing | 1°X360 | 1°X360 | 1°X360 |

| Worktable load | 500kg | 1000kg | 1500kg |

| travel(X axis /Y axis /Z axis) | 650/550/550mm | 950/750/830mm | 1300/900/900mm |

| Distance from spindle nose to worktable | 180mm-750mm | 170mm-1000mm | 180mm-1080mm |

| Distance from spindle center to worktable | 120-690mm | 120-870mm | 100-1000mm |

| Spindel taper | BT40 | BT50 | BT50 |

| Spindle speed | 6000rpm | 6000rpm | 6000rpm |

| Fast move speed(X/Y/Z) | 15m/min | 24m/min | 24m/min |

| Tool | 30 pcs | 40 pcs | 40 pcs |

| Tool changing time | 2.5 sec | 5.5 sec | 5.5 sec |

| Tool size | Φ80x320mm | Φ125x350mm | Φ125x350mm |

| Tool weight | 15kg | 25kg | 25kg |

| Accuracy (300mm) | ±0.012mm | ±0.012mm | ±0.012mm |

| Repositioning accuracy | 0.008mm | 0.008mm | 0.008mm |

| weight | 12000kg | 14000kg | 18000kg |