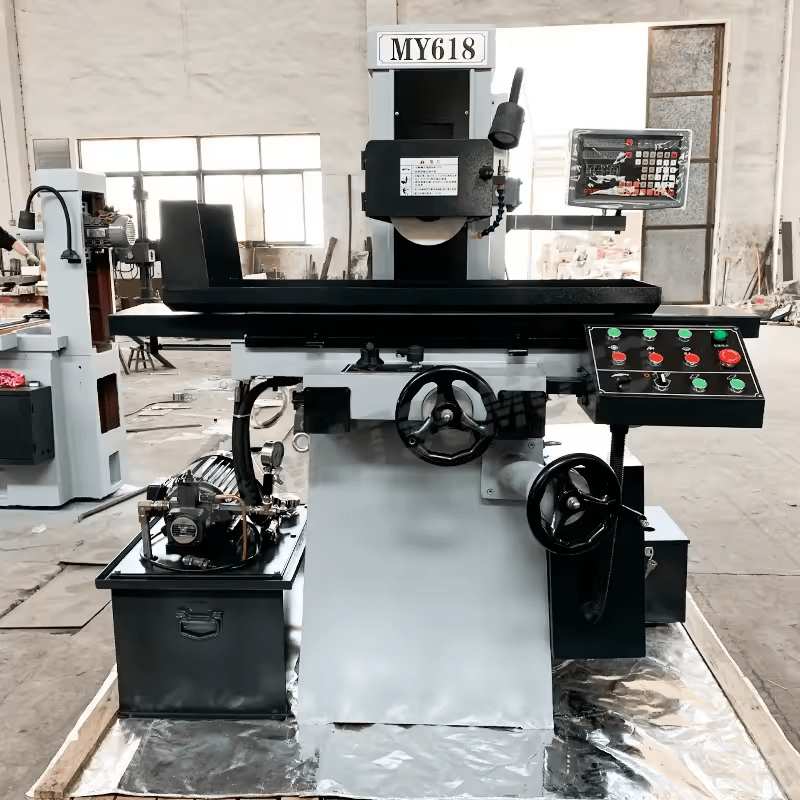

Surface grinding machine MY618

Function

Surface grinding machine is a kind of grinding machine.The main grinding wheel is used to rotate and grind the workpiece to achieve the required flatness. According to the shape of the worktable, it can be divided into two kinds: rectangular worktable and circular worktable. The main parameters of the surface

grinding machine of the rectangular worktable are the width and length of the worktable, and the main parameters of the circular worktable are the diameter of the worktable.According to the different types of shaft can be divided into horizontal shaft and vertical shaft grinding machine.

Description

Surface grinding machine MY618

Application:

* The Surface Grinder is reasonable in structure, good rigidity, beautiful appearance, convenient operation.

* The surface grinding machine using precision plastic guide surface and precision scraping, grinding imported hydraulic

transmission, drive by synchronous .

* The hydraulic surface grinder main mechanical valve is a special valve grinder, is divided into two parts, the mechanical

commutation control, throttle control. Throttle control part and unloading function. can realize the station start and stop.

* Grinding can be all kinds of plane and complex shaped surface, suitable for motor without grinding the feed, according to user needs with a permanent magnet sucker or electromagnetic sucker.

* The Surface Grinder is reasonable in structure, good rigidity, beautiful appearance, convenient operation.

* The surface grinding machine using precision plastic guide surface and precision scraping, grinding imported hydraulic

transmission, drive by synchronous .

* The hydraulic surface grinder main mechanical valve is a special valve grinder, is divided into two parts, the mechanical

commutation control, throttle control. Throttle control part and unloading function. can realize the station start and stop.

* Grinding can be all kinds of plane and complex shaped surface, suitable for motor without grinding the feed, according to user needs with a permanent magnet sucker or electromagnetic sucker.

| Model | unit | MY618 | MY820 | MY1022 | MY1224 | MY1230 | MY1232 | ||

| Bench | Worktable size(L×W×) | m | 460×180 | 480×200 | 540×250 | 600×300 | 700×300 | 800×320 | |

| Max. travel of table (L×W) | m | 500×190 | 530×220 | 560×260 | 630×320 | 760×370 | 860×380 | ||

| Table Max. cutting area (L×W) | m | 500×190 | 530×220 | 560×260 | 630×320 | 760×370 | 860×380 | ||

| Number of T-Slot | mm | 1×12 | 1×14 | 1×14 | 1×14 | 1×14 | 1×14 | ||

| The grinding head | Distance From Table Surface To Spindle Center | mm | 450 | 450 | 450 | 490 | 540 | 540 | |

| Wheel Size(dia×width×bore) | mm | 200×20×31.75 | 200×20×31.75 | 200×20×31.75 | 300×30×75 | 300×30×75 | 335×30×127 | ||

| Spindle speeds | r/m | 335 | 2850 | 2850 | 1440 | 1440 | 1440 | ||

| The amount of feed | Table longitudinal (left and right)speed (stepless) | m/min | 3-23 | 3-20 | 3-20 | 3-20 | 5-25 | 5-25 | |

| Table horizontal (before and after)the amount of feed | Continuous (variable speed) | mm/min | 150 | 150 | 150 | 150 | 150 | 150 | |

| Intermittent (stepless) | mm/ | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | ||

| The handwheel rotates | mm | 2.5 | 2.5 | 4 | 4 | 4 | 4 | ||

| Hand wheel each grid | mm | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | ||

| Vertical(up and down)feed wheel feed | The handwheel rotates | mm | 1.25 | 1.25 | 2 | 2 | 2 | 2 | |

| Hand wheel each grid | mm | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | ||

| Motor power | Spindle motor | kw | 1.5 | 1.5 | 1.5 | 4 | 4 | 4 | |

| Cooling motor | w | 40 | 40 | 40 | 40 | 40 | 40 | ||

| Hydraulic system | Hydraulic motor | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Working Pressure | Mpa | 3 | 3 | 3 | 3 | 3 | 3 | ||

| Oil tank capacity | L | 80 | 80 | 80 | 80 | 80 | 80 | ||

| Max. Capacity | L/min | 18 | 18 | 18 | 18 | 18 | 18 | ||

| Working precision | The machined surface of the base of parallelism | mm | 300/0.005 | 300/0.004 | 300/0.004 | 300/0.004 | 300/0.004 | 300/0.004 | |

| Surface Roughess | μm | Ra0.32 | Ra0.32 | Ra0.32 | Ra0.32 | Ra0.32 | Ra0.32 | ||

| Weighe of machine | Net | T | 0.81 | 1.05 | 1.25 | 1.5 | 2.1 | 2.5 | |

| Cross | T | 0.85 | 1.15 | 1.35 | 1.65 | 2.35 | 2.75 | ||

| Packing size (L×W×H) | mm | 1700×1250×1900 | 1700×1300×1920 | 1750×1350×1960 | 1950×1700×2030 | 1950×1700×2030 | 2000×1800×2030 | ||

| Characteristics of machine tools: | |||||||||

| 1.The machine is reasonable in structure, good rigidity, beautiful appearance,convenient operation. | |||||||||

| 2.Using precision plastic guide surface and precision scraping, grinding imported hydraulic transmission, drive by synchronous. | |||||||||

| 3.The main mechanical valve is a special valve grinder, is divided into two parts,the mechanical commutation control, throttle control. Throttle control part and unloading function, can realize the station start and stop. | |||||||||

| 4.Grinding can be all kinds of plane and complex shaped surface, suitable for motor without grinding the feed, according to user needs with a permanent magnet sucker or electromagnetic sucker. | |||||||||