CNC line rail and hard rail: what is the difference?

The guide rail and the bed of the hard rail are an integral casting, and then the guide rail is processed on the basis, and then the guide rail is processed by stainless steel shot quenching and grinding. The hard rail is a guide rail with sliding friction, good rigidity and strong bearing capacity.

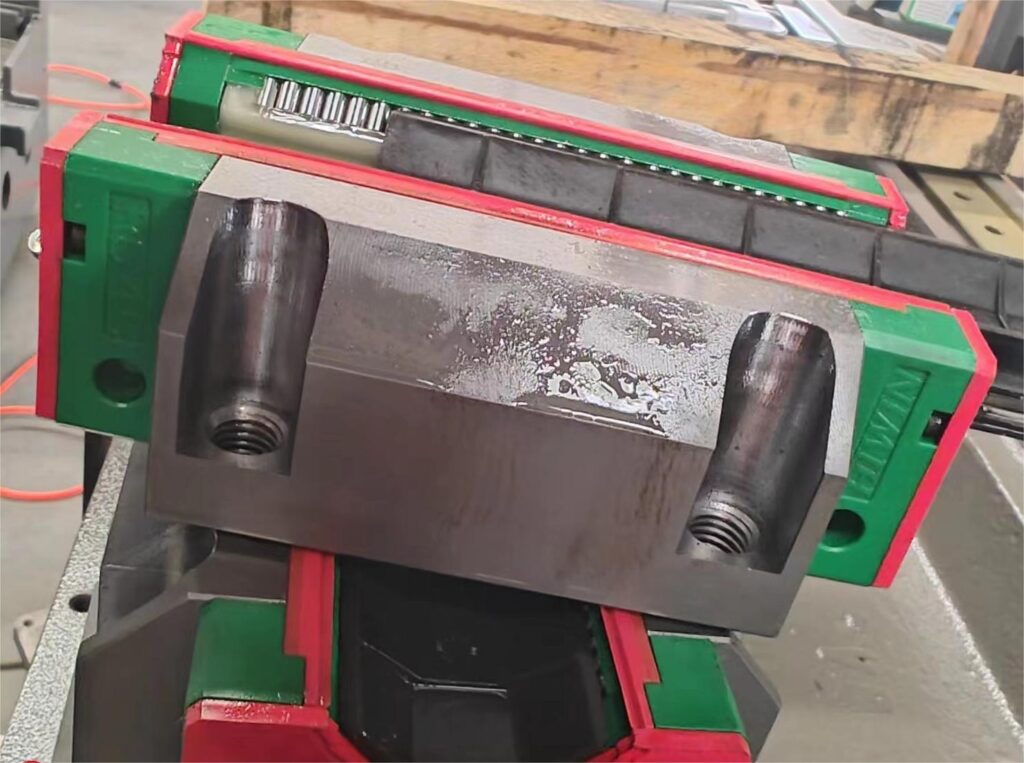

Line rails usually refer to rolling guides, and such components are often called “linear guides”. The linear guide itself is divided into two parts: the slide rail and the slider. There are balls or rollers in the slider, and the length of the slide rail can be customized. It is a modular component, which is a standardized and serialized individual product produced by a special manufacturer. It can be installed on the machine tool, and can be disassembled and replaced after wear and tear.

The line rail is rolling friction, fast speed, small resistance, and convenient lubrication. Now more and more line rails are used in the machine tool industry. The CNC milling machines and CNC inclined bed lathes produced by DH cnc use HIWIN line rails and roller type line rails. ,as the picture shows.

The difference between CNC line rails and hard rails is: different components, different moving speeds, and different uses and functions.

different components

- CNC line rail: CNC line rail is separated from the rolling guide rail and the bed, and is moved and processed by the balls or rollers circulating inside the slider

- CNC hard rail: CNC hard rail is a casting in which the guide rail and the bed are integrated, and then the guide rail is processed on the basis of the casting.

different speed of movement

- CNC line rail: The running speed of CNC line rail is extremely fast, and after pre-tightening treatment, it can achieve zero gap between tracks and high precision.

- CNC hard rail: CNC hard rail belongs to dry friction. Due to the large contact surface, the friction resistance is also relatively large, and the moving speed cannot be too fast.

different functions

- CNC line rail: CNC line rail is suitable for processing products and small precision molds.

- CNC hard rail: CNC hard rail is suitable for heavy cutting, large molds, high hardness workpieces, and workpieces with general precision requirements.