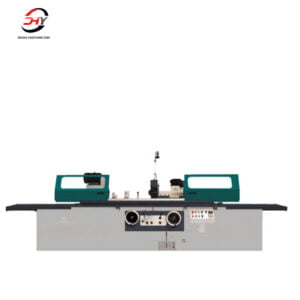

A hydro-dynamic system produces an oil film between bushing and spindle to reduce vibration ensuring maximum precision and surface quality. This type of bearing increase the spindle’s life and stability The table features large dimensions and swivels in two directions – table movement via hand-wheel or automatically via linear hydraulic feed Very solid workpiece spindle head and wide, rigid grinding spindle support with inside grinder ensure the best possible results under varying operating conditions Grinding spindle supported on both sides in an adjustable 3-segment bushing A dwell time can be set at the end of the table travel Accuracy tested in accordance with ISO for cylindrical grinding machines The sturdy spindle head swivels 30° To the left and the right Pawl-feed in combination with a zero-stop allows repeated feed without checking the feed scale Including inside grinding feature and automatic infeed Hydraulic or manual rapid feed with return Infinitely variable feed