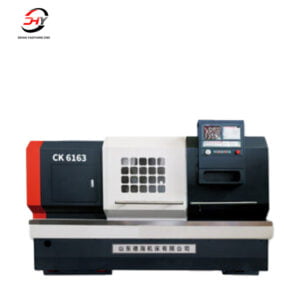

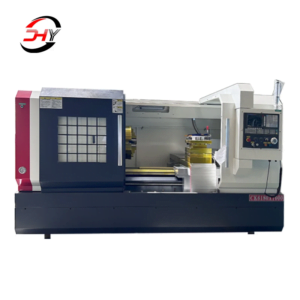

CNC flat bed lathe CK61125

Machine tool processing objects and uses: It can process shafts and pipe parts; shaft (or disk) parts with complex geometric shapes, various sizes and high precision requirements. Machining of cylindrical, conical, stepped, spherical and other types of rotary surface parts. Processing various metric and imperial internal and external threads. In addition to turning, it can also be used for drilling, expanding, reaming and boring.