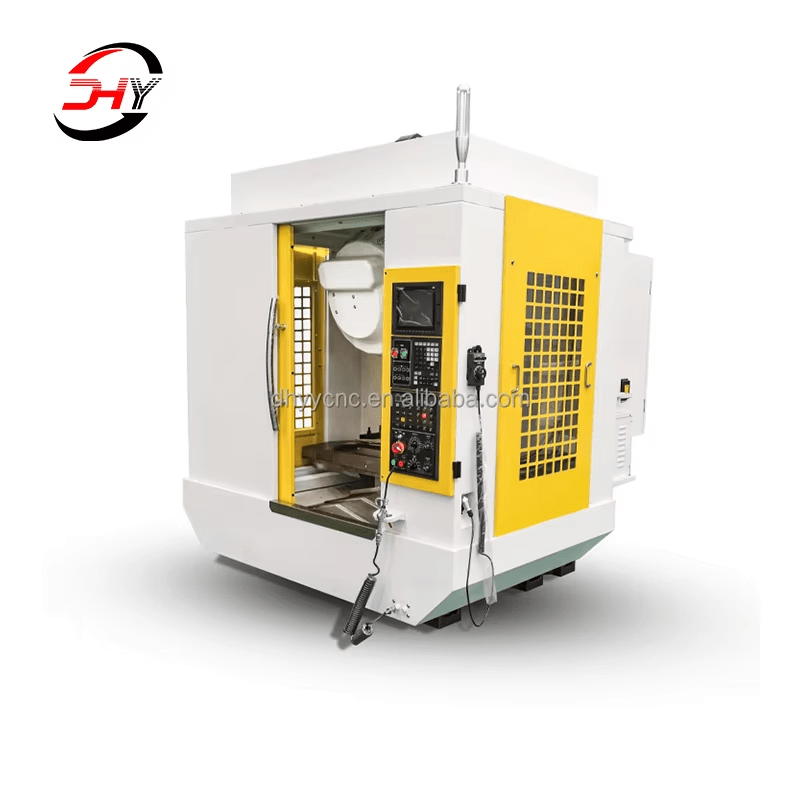

CNC drilling and tapping center T700

Vertical drilling and tapping center is mainly used to process plate, disc, shell, mold and other parts with high precision, multiple processes and complex shape. It can continuously complete milling, drilling, reaming, reaming, boring, tapping and precise machining of two-dimensional three-dimensional curved surface and inclined plane in one clamping process. The processing is programmed and the production cycle is shortened, so that users can obtain good economic benefits.

Description

CNC drilling and tapping center T700

Such cnc tapping center has following features:

1. the foundation, column, main spindle box, cross sliding table,worktable and other parts were designed with high strength casting technology.;

2. the inner metallographic structure is very steady.;

3. the casting parts show rational geometry composition through machine tool kinetics and finite element analysis.;

4. the basic parts have high steel nature by collocating with the reinforcing rib.;

5. with the wide foundation, box-shaped cavity column, broaden & lengthening sliding base and advanced design of mechanics of materials, the weight capacity can be ensured.;

6. High speed and high precision spindle, 20000- 24000rpm:;

7. CE Standard and CE Certificate.

| Item | Unit | T600 | T700 | |

| Travel | XYZ Travel | mm | 600/400/350 | 700/400/350 |

| Distance from Spindle Nose to Table | mm | 135-485 | 135-485 | |

| Worktable | Table Size | mm | 700x420 | 700x420 |

| Max.Loading on Table | KG | 250 | 250 | |

| Spindle | Spindle Taper | BT30 | BT30 | |

| Spindle Speed | rpm | 20000rpm | 20000rpm | |

| Spindle Motor Power | KW | 3.7/5.5 | 3.7/5.5 | |

| Feeding | Rapid Feedrate(X/Y/Z) | m/min | 48/48/48 | 48/48/48 |

| Cutting Feedrate(X/Y/Z) | m/min | 1-10000 | 1-10000 | |

| Toll magazine | No.of Tools | pcs | 16/21T | 16/21T |

| Tools Size(Full Tools) | mm | 50/120 | 50/120 | |

| Max.Tool Weight | KG | 3 | 3 | |

| Toll change time | sec | 1.6 | 1.6 | |

| Accuracy | Positioning Accuracy | mm | ±0.005/300 | ±0.005/300 |

| Re-Positioning Accuracy | mm | ±0.003/300 | ±0.003/300 | |

| Others | machine size | mm | 2200x1900x2300 | 2200x1900x2300 |

| Machine Height | mm | 2900 | 3100 | |

| Such cnc tapping center has following features; | ||||

| 1. the foundation, column, main spindle box, cross sliding table,worktable and other parts were designed with high strength casting technology; | ||||

| 2. the inner metallographic structure is very steady; | ||||

| 3. the casting parts show rational geometry composition through machine tool kinetics and finite element analysis; | ||||

| 4. the basic parts have high steel nature by collocating with the reinforcing rib; | ||||

| 5. with the wide foundation, box-shaped cavity column, broaden & lengthening sliding base and advanced design of mechanics of materials, the weight capacity can be ensured; | ||||

| 6. High speed and high precision spindle, 20000- 24000rpm; | ||||

| 7. CE Standard and CE Certificate. | ||||