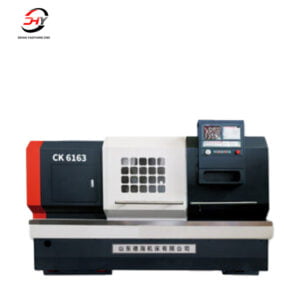

CNC flat bed lathe CK61125

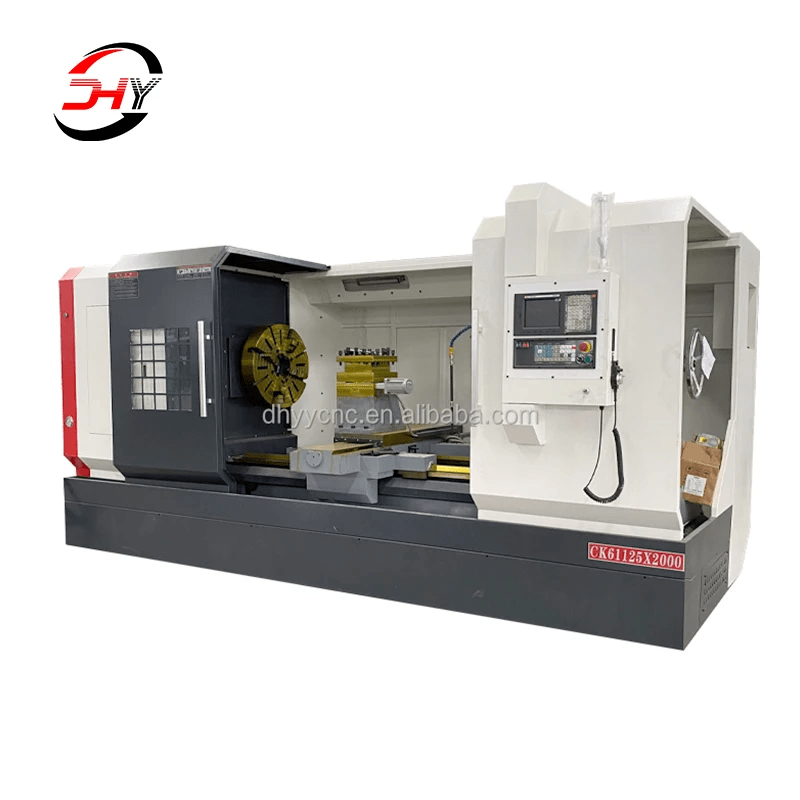

Machine tool processing objects and uses: It can process shafts and pipe parts; shaft (or disk) parts with complex geometric shapes, various sizes and high precision requirements. Machining of cylindrical, conical, stepped, spherical and other types of rotary surface parts. Processing various metric and imperial internal and external threads. In addition to turning, it can also be used for drilling, expanding, reaming and boring.

Description

CNC flat bed lathe CK61125

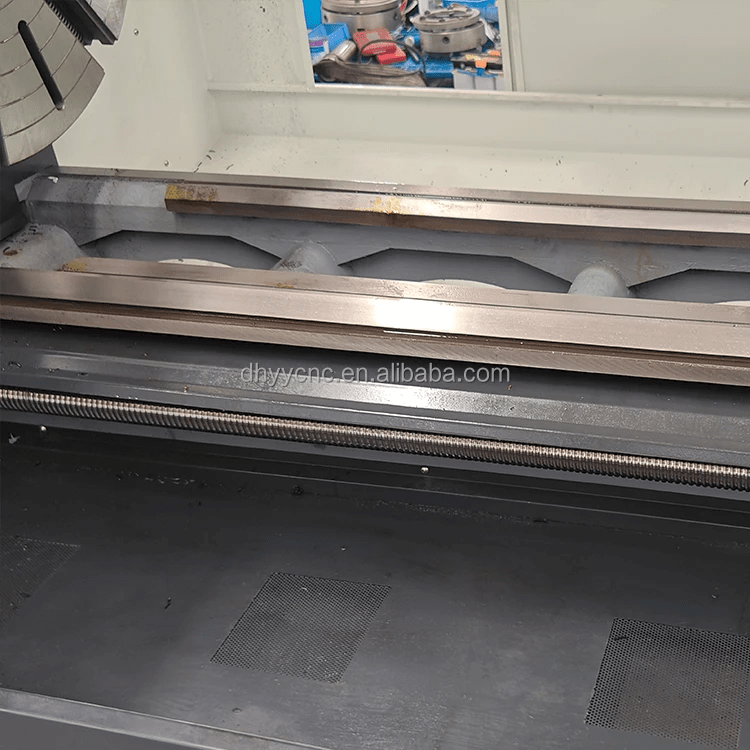

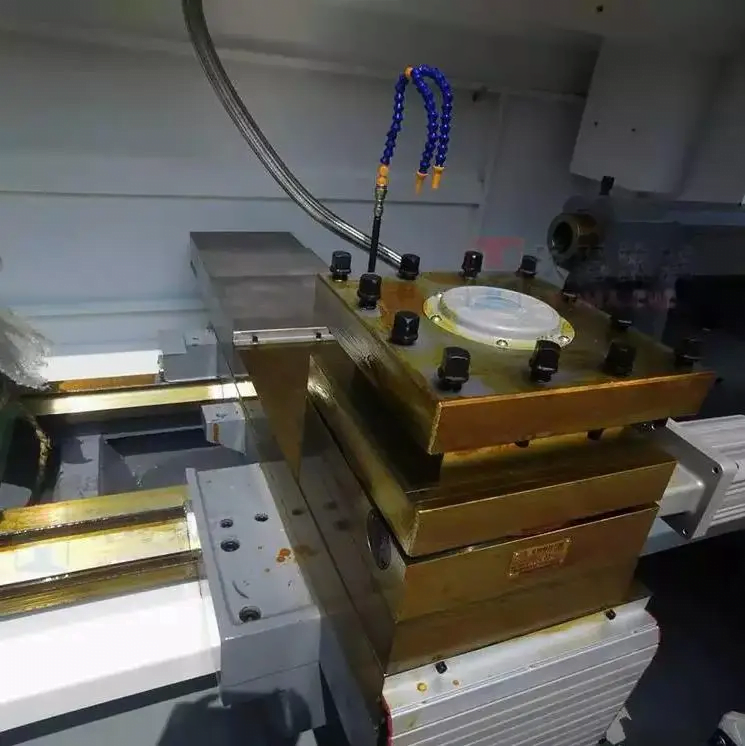

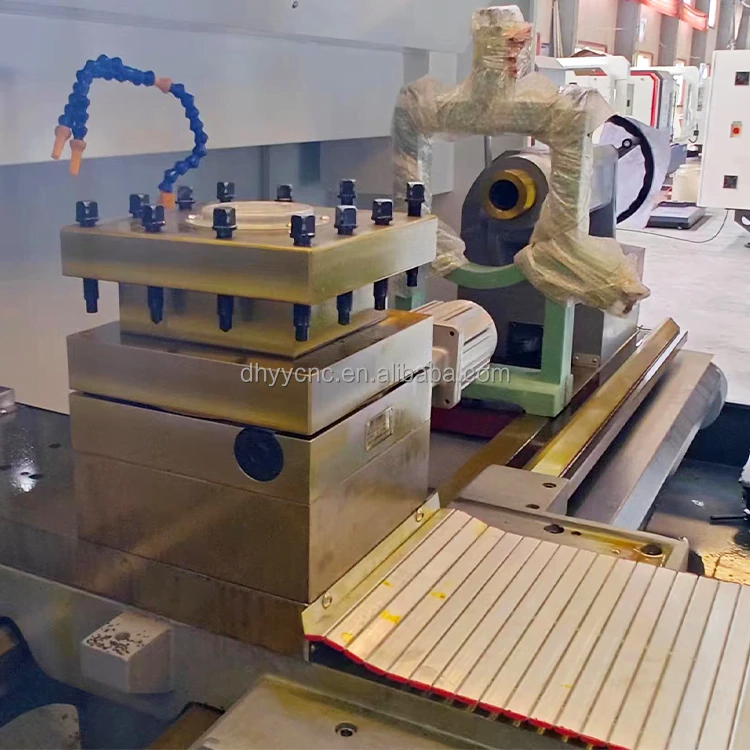

Features of the machine tool: 1) Mechanical, electrical and hydraulic integration and modular design, reasonable layout, compact structure, pleasant operation and convenient maintenance. 2) It adopts reinforced bed and integral bed foot, and the guide rail is pasted with plastic, which has the characteristics of good rigidity and high processing precision. 3) The main shaft adopts domestic famous brand bearings, and is equipped with an external separate lubrication system. The screw bearing adopts high-precision matched screw bearings, which have high precision and long service life. 4) It adopts Chinese brand tool holder, which has good rigidity and high precision. 5) Automatic centralized lubrication device, sufficient and reliable lubrication, automatic control of lubrication cycle. 6) AC servo motor is adopted, with high positioning accuracy and stable and reliable performance. 7) The special motor and frequency converter for the spindle are used to realize three-speed stepless speed regulation with a wide range of speed changes. Stepless speed change and constant linear speed cutting can be realized in each gear. Closed protection design, no water leakage, no oil leakage, beautiful appearance.

| SPECIFICATIONS | Units | CK61100 | CK61125 | CK61140 |

|---|---|---|---|---|

| Swing over bed | mm | 1000 | 1250 | 1400 |

| Swing over cross slide | mm | 610 | 850 | 1000 |

| Distance between centers | mm | 1500/3000/4000/5000/6000 | 1500/3000/4000/5000/6000 | 1500/3000/4000/5000/6000 |

| Guideway width | mm | 755 | 755 | 755 |

| Max. load capacity | T | 6 | 6 | 6 |

| Spindle bore | mm | 130 | 130 | 130 |

| Spindle bore taper | - | Metric φ140/MT6 | Metric φ140/MT6 | Metric φ140/MT6 |

| Spindle nose type | - | A2-15 | A2-15 | A2-15 |

| Spindle speed steps | - | VF. 4 steps | VF. 4 steps | VF. 4 steps |

| Spindle speed range | rpm | 4-300 | 4-300 | 4-300 |

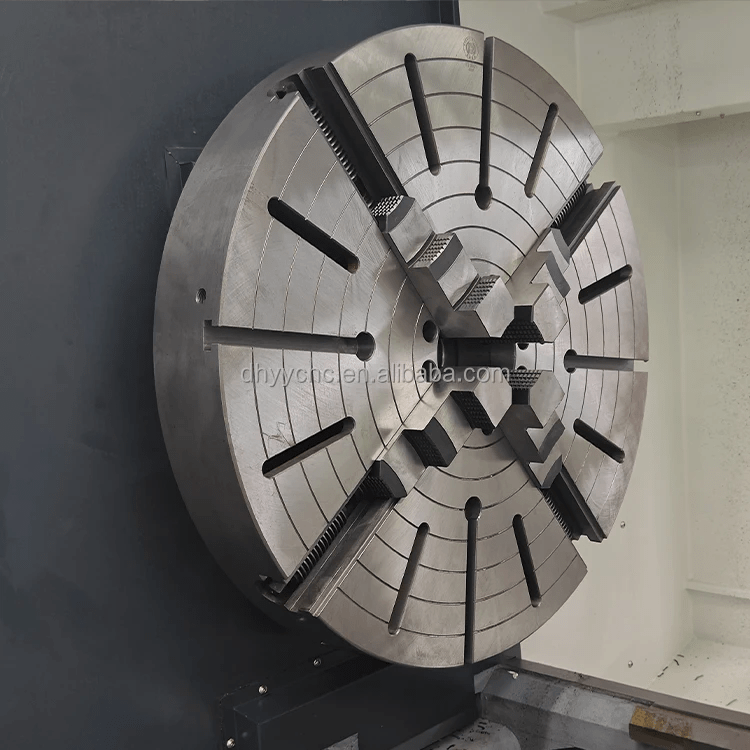

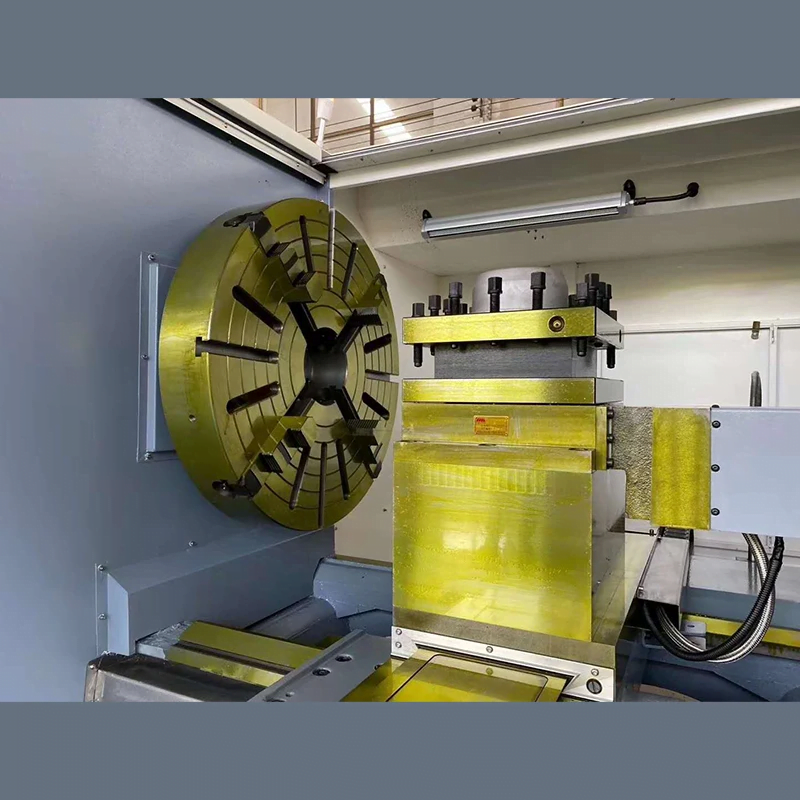

| Chuck | mm | φ800 4-jaw manual | φ1000 4-jaw manual | φ1000 4-jaw manual |

| Turret/tool post | - | Eletric 4 position | Eletric 4 position | Eletric 4 position |

| Tool size | mm | 40 x 40 | 40 x 40 | 40 x 40 |

| X axis travel | mm | 520 | 620 | 720 |

| Z axis travel | mm | 1350/2850/3850/4850/5850 | 1350/2850/3850/4850/5850 | 1350/2850/3850/4850/5850 |

| X axis rapid traverse | mm/min | 4000 | 4000 | 4000 |

| Z axis rapid traverse | mm/min | 6000 | 6000 | 6000 |

| Tailstock quill diameter | mm | φ160 | φ160 | φ160 |

| Tailstock quill taper | - | MT6 | MT6 | MT6 |

| Tailstock quill travel | mm | 300 | 300 | 300 |

| Main spindle motor | kw | 22 | 22 | 22 |

| Coolant pump motor | kw | 0.125 | 0.125 | 0.125 |

| Weight for 1500 | kg | 10000 | 11000 | 12000 |

| Weight for 3000 | kg | 11500 | 12500 | 13500 |

| Weight for 4000 | kg | 12500 | 13500 | 14500 |

| Weight for 5000 | kg | 13500 | 14500 | 15500 |

| Weight for 6000 | kg | 14500 | 15500 | 16500 |

| Dimension for 1500 | mm | 5000x2100x2100 | 5000x2250x2300 | 5000x2250x2300 |

| Dimension for 3000 | mm | 6500x2100x2100 | 6500x2250x2300 | 6500x2250x2300 |

| Dimension for 4000 | mm | 7500x2100x2100 | 7500x2250x2300 | 7500x2250x2300 |

| Dimension for 5000 | mm | 8500x2100x2100 | 8500x2250x2300 | 8500x2250x2300 |

| Dimension for 6000 | mm | 9500x2100x2100 | 9500x2250x2300 | 9500x2250x2300 |

.png)