CNC gear hobbing machine YK31125

The machine can be customized with four-axis or five-axis models according to user needs.

Description

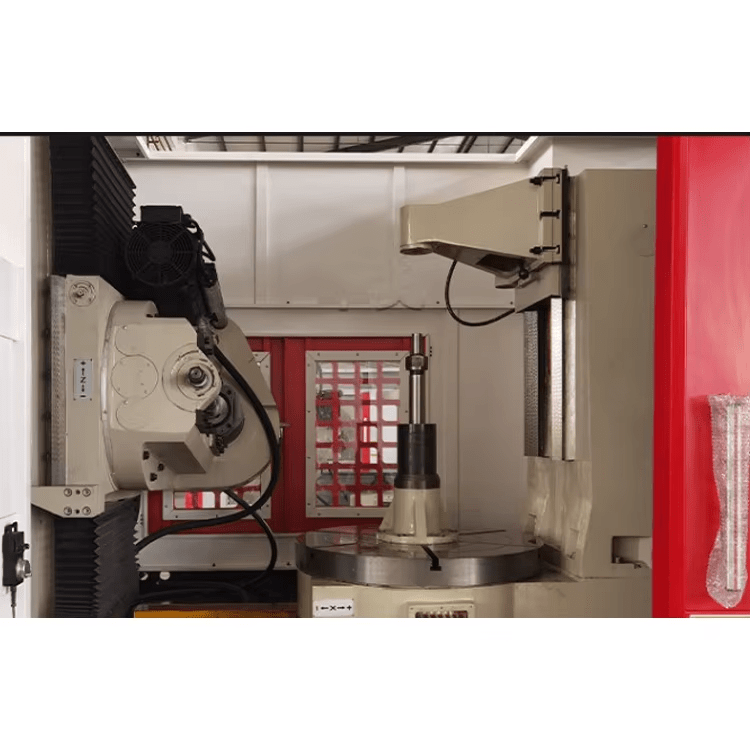

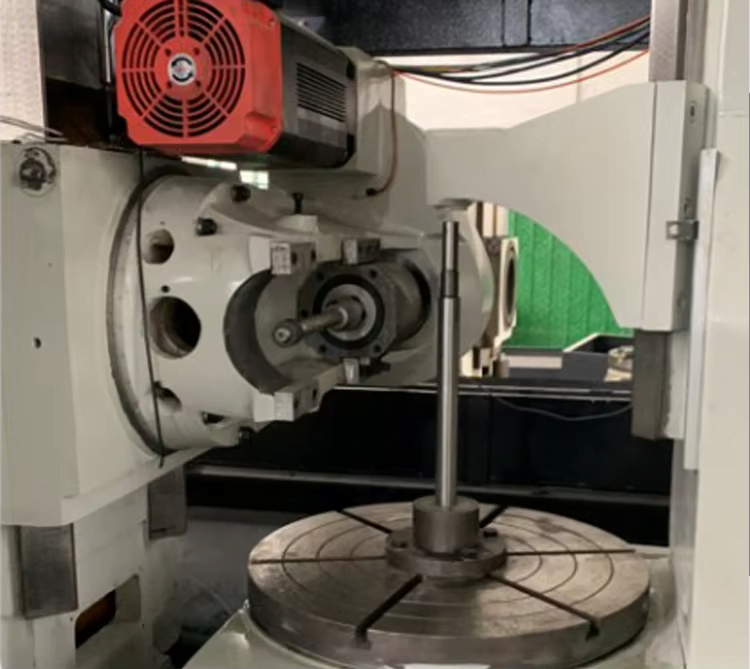

CNC gear hobbing machine YK31125

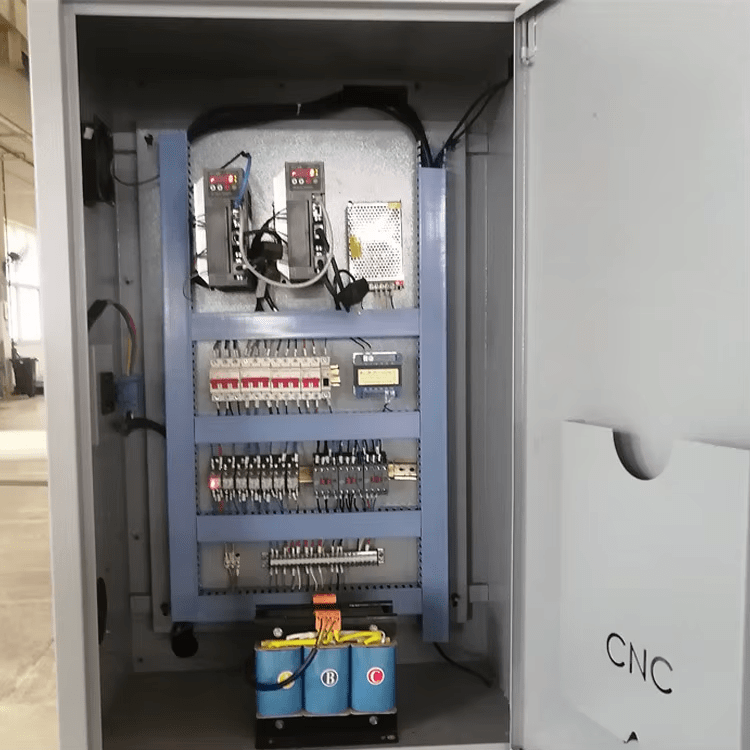

YK series CNC gear hobbing machine tailstock has high rigidity and heavy weight, which can ensure stable gears, high machining accuracy, and easy replacement of taper thimbles. The hob shaft has good stability and high precision, and is suitable for milling cylindrical gears. With high hardness, high frequency, high precision three-jawchuck, easy clamping, automatic centering. The slide rail adopts high frequency quenching process, which has high rigidity and long service life. The servo motor is used to individually control the feed axis through the nu-merical control svstem, the feed axis of the numerical control machine tool,and the feed system of the numerical control machine tool to meet the basic requirements of no gap, low friction, and high rigidity. The machine tool is equipped with a rapid movement device of the tool rest and an automatic stop operation mechanism when cutting is terminated, sothis machine tool is not only widely used in gear processing, but also easy to operate. Compact structure, high power, good rigidity, high degree of automation, capable of high-speed strong cutting, easy adjustment, and automatic parkingdevice. The gear shifting has a wide shifting adjustment and processing range, which improves safety and reliability. The equipment can be equipped with processing accessories such as indexing head and circular table. The open motion control card is used to drive the motors of each axis, giving full plav to the advantages of software and hardware on the CNC platform,and enriching and improving the development environment. The spindle motor is directly installed on the tool rest and is transmitted to the hob spindle through three pairs of high-precision cylindrical helical teeth,which reduces the transmission error and improves the transmission accurary. The worktable adopts high-precision double-lead turbine worm drive, and is designed with a damping mechanism, There is also an unloading oil cylinder under the worktable to reduce the load of the C-axis motor and prolong the service life of the circular quide rail of the worktable. The main quide rail is processed by hard rail quenching and plastic sticking,which ensuring the durability of the machine tool. The Z-axis movement adopts a new structure of balanced oil cylinder and chain counterweight, which makes the hob better balance when cutting up and down, so cutting is more stable, and service life of the ball screw can be effectively extended.

| Machine specification | YK31125 CNC4 |

| Max processing diameter (mm) | 1600 |

| 1000 | |

| Max processing module (mm) | 16mm |

| Max Pricessing teeth with | 500mm |

| Max Rotating angle | ±60° |

| Minimum number of teeth processed | 12 |

| Maximum vertical travel of tool holder | 800mm |

| Cutter speed | 20~250 r/min |

| Max cutter diameter | 245 |

| Max cutter length | 220 |

| Spindle Taper | MT6 |

| The distance from spindle center to worktable center | 100~900 mm |

| Hob Arbor Diameter | φ27 φ32 φ40 φ50 |

| Distance from workbench to lower end of rear column support | 700~1200mm |

| Max loading weight | 3000kg |

| Worktable diameter | 950 mm |

| Worktable hole diameter | 200 mm |

| Hob spindle transmission speed ratio | 1:10 |

| Worktable rotating speed | 16-500 r/min |

| Radial direction feeding speed | 0~3000 mm/min |

| Axis direction feeding speed | 0~3000 mm/min |

| Machine total weight approx. | 15000kg |