CNC horizontal lathe CK61100

Standard configuration:

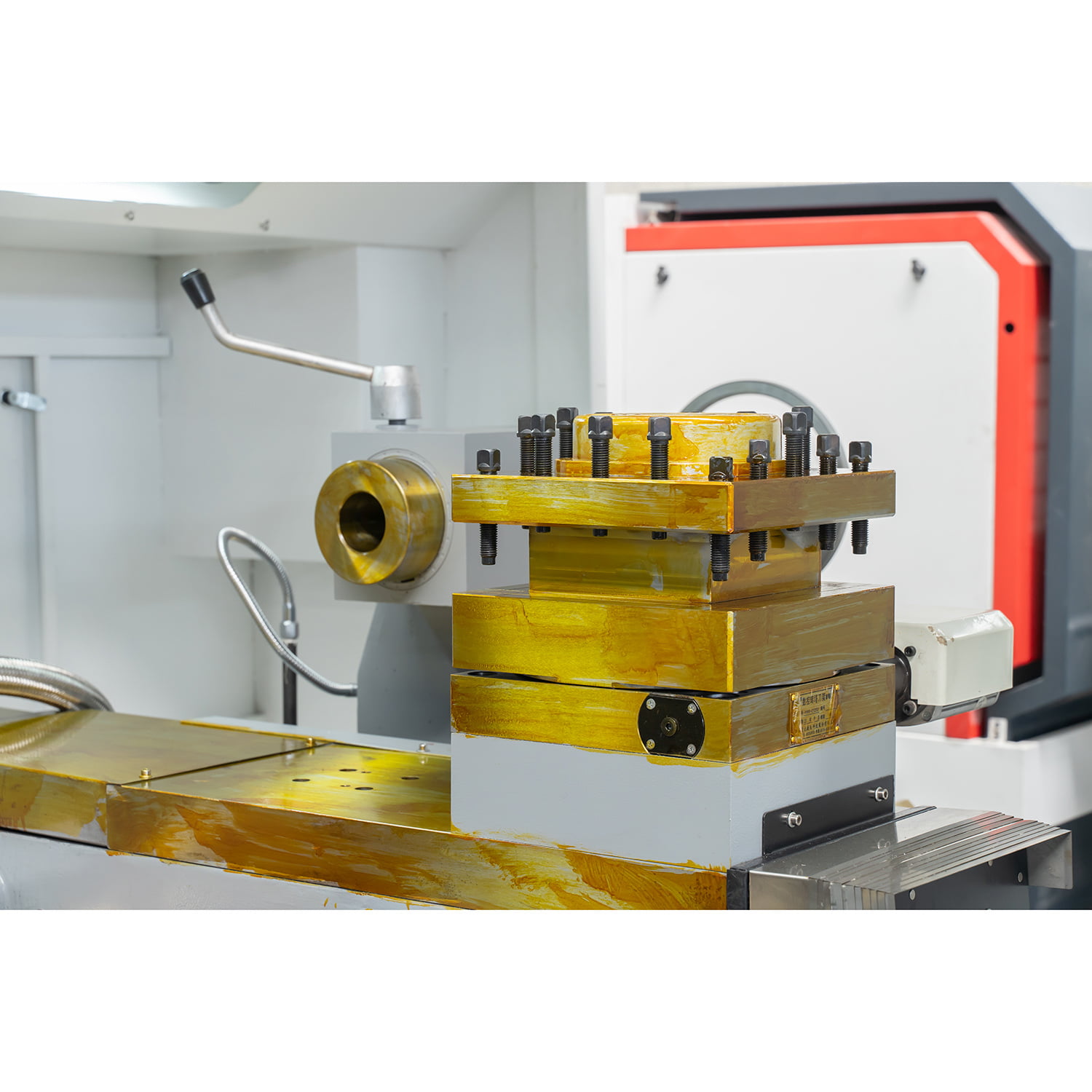

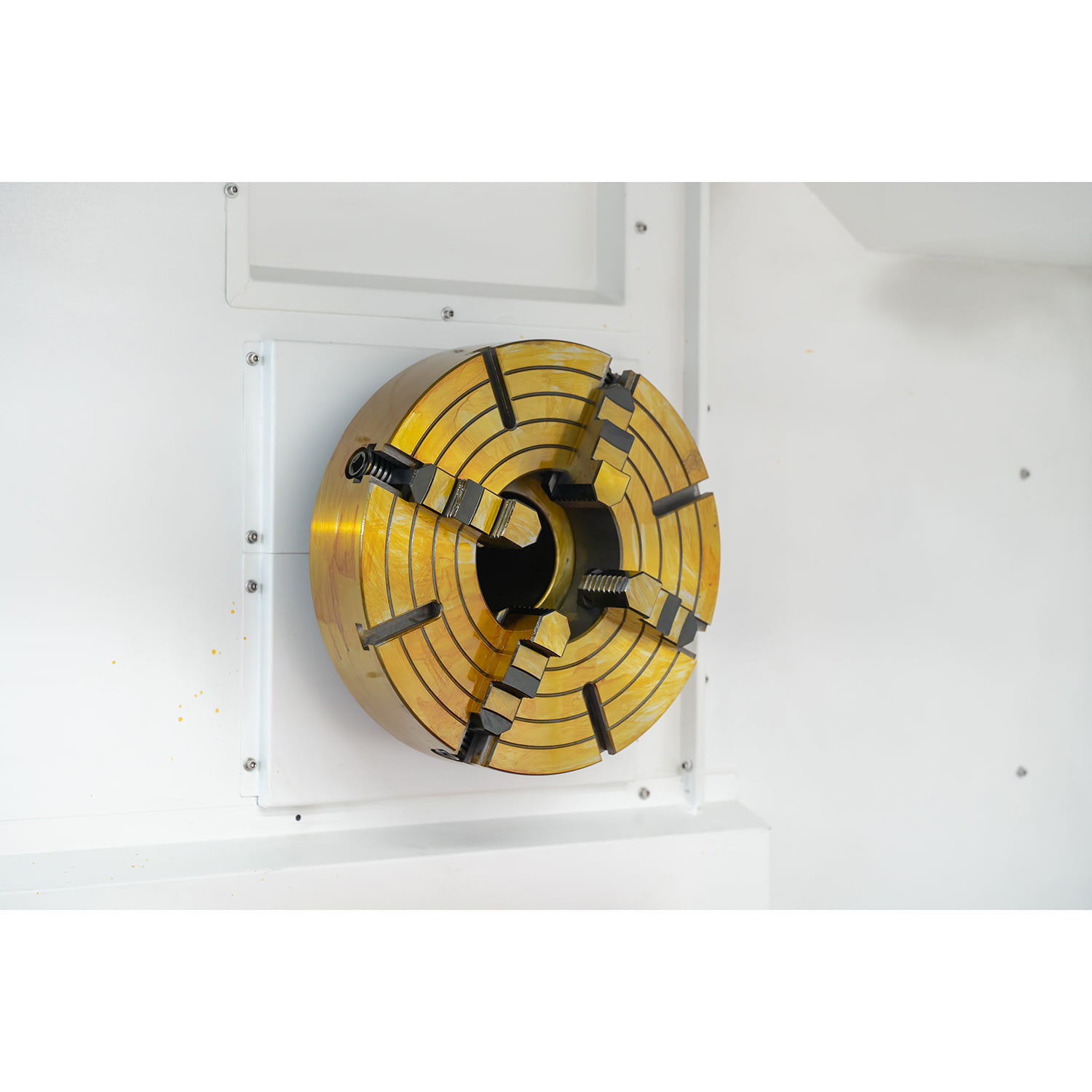

Four-station electric tool rest, three-jaw chuck, manual tailstock, automatic centralized lubrication, cooling system, fully enclosed protection

Optional

Siemens, Fanuc, Guangshu, Kaide and other CNC systems, horizontal or electric turret, pneumatic or hydraulic chuck, hydraulic tailstock.

Description

CNC horizontal lathe CK61100

◎The whole bed is cast by resin sand technology, and after aging treatment, it has beautiful appearance, good rigidity and high precision

◎The surface of the guide rail is quenched by supersonic frequency, which has extremely high precision retention, high hardness and long service life

◎High-quality scraper plates are used to prevent scratches on the guide rails, and the surface of the guide rails is plastic-coated, with good wear resistance and high precision.

| Specification | CK6180 | CK61100 | |||

|---|---|---|---|---|---|

| Swing over bed | mm | 800 | 1000 | ||

| Swing over cross slide | mm | 480 | 680 | ||

| Maximum processing length | mm | 1000/1500/2000/3000/4000/5000/6000 | 1000/1500/2000/3000/4000/5000/6000 | ||

| Guideway width | mm | 600 | 600 | ||

| Max.load capacity | T | 4 | 4 | ||

| Spindle bore | mm | 104 | 104 | ||

| Spindle bore taper | Metric 120/MT5 | Metric 120/MT5 | |||

| Spindle nose type | C11 | C11 | |||

| Spindle speed steps | VF.3steps | HYD.4 steps | VF.3 steps | HYD.4 steps | |

| Spindle speed range | rpm | 10-800 | 17-800 | 10-800 | 17-800 |

| Chuck | mm | 400/3-jaw manual | 400/3-jaw manual | ||

| Turret/tool post | Electric 4 position | Electric 4 position | |||

| Tool size | mm | 32*32 | 40*40 | ||

| X axis travel | mm | 420 | 520 | ||

| Z axis travel | mm | 850/1350/1850/2850/3850/4850/5850 | 850/1350/1850/2850/3850/4850/5850 | ||

| X axis rapid traverse | mm/min | 4000 | 4000 | ||

| Z axis rapid traverse | mm/min | 6000 | 6000 | ||

| Tailstock quill diameter | mm | φ120 | φ120 | ||

| Tailstock quill taper | MT6 | MT6 | |||

| Tailstock quill travel | mm | 250 | 250 | ||

| Main motor power | kw | 15 | 15 | ||

| Coolant motor power | kw | 0.125 | 0.125 | ||

| Weight for 1000 | kg | 4800 | 5000 | ||

| Weight for 1500 | kg | 5200 | 5400 | ||