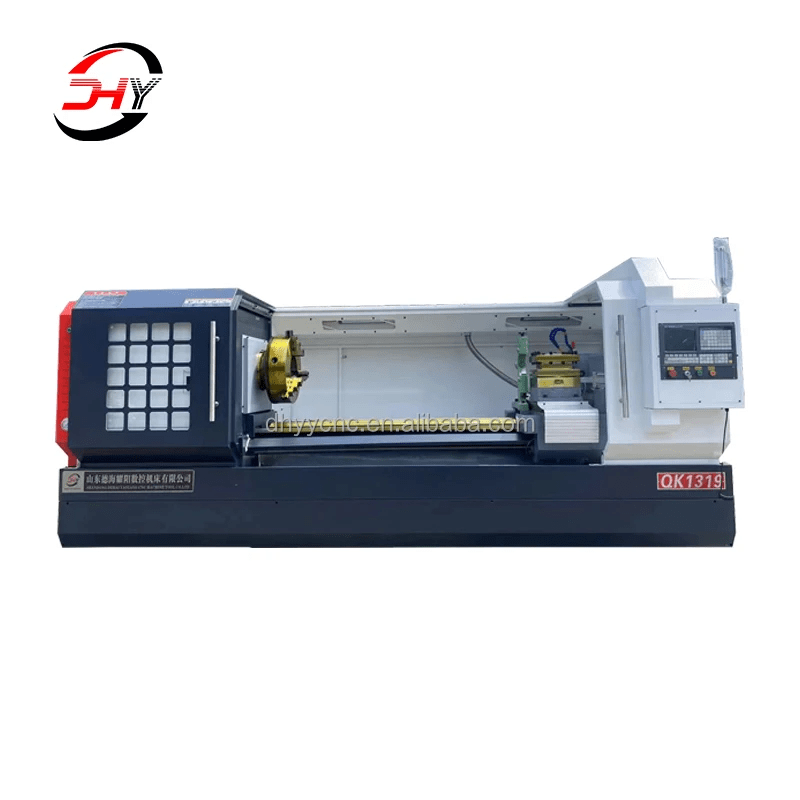

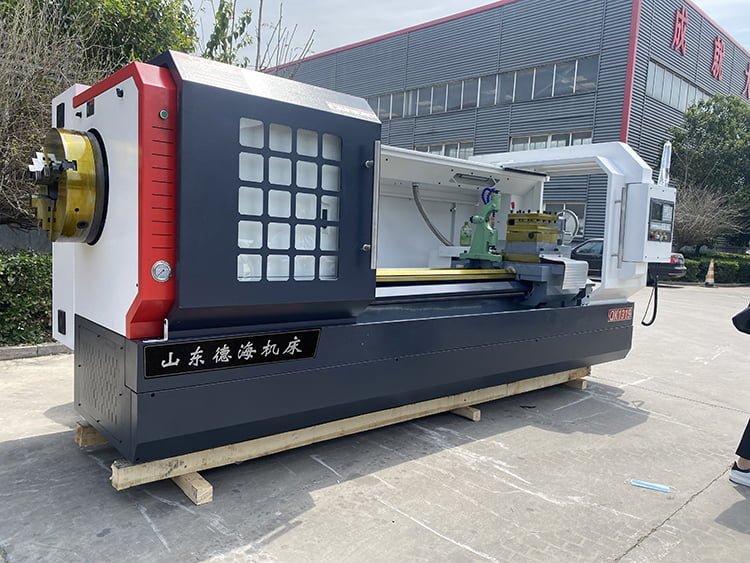

CNC pipe thread lathe QK1319

Optional:CNC systems such as Siemens, FANUC, Guangshu and Kandi, fully enclosed protective covers, vertical and horizontal turrets.

- Standard configuration:

- Four-station electric knife holder, automatic centralized lubrication system, air-conditioning system, semi-closed protective cover

Description

CNC pipe thread lathe QK1319

QK1319 high-speed CNC pipe thread lathe is mainly used for processing internal and external threads of pipe tools, and has the function of CNC lathe, which can process the outer circle, inner hole and end surface of workpieces such as shafts and discs;

- Widely used in the processing and repair of drill pipes, joints, casings and other parts in some industries, and also used in thread processing of various pipes and drill pipes in chemical, coal, geological and other industries.

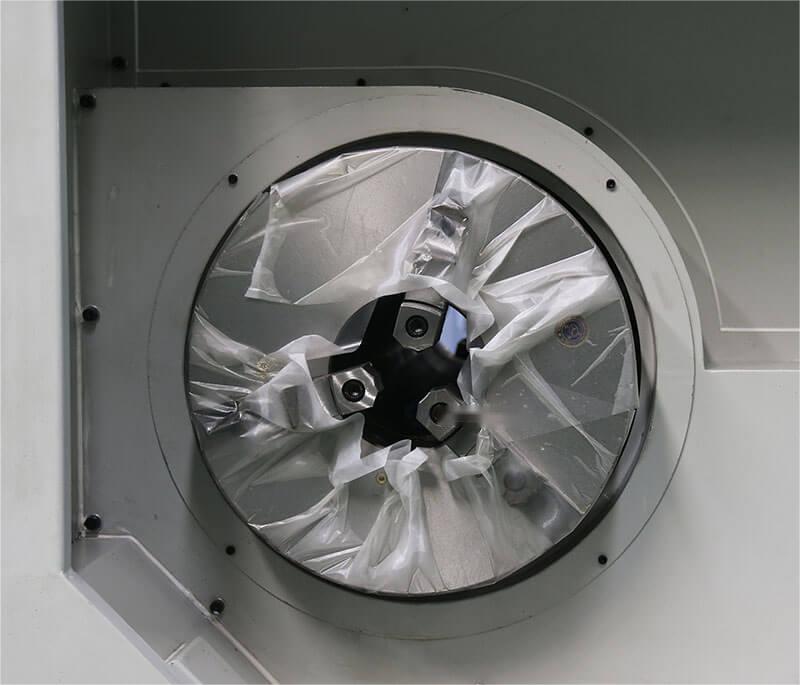

- Features:Spindle hole diameter drilling, high passability, double chuck workpiece clamping stability. High-quality high-strength cast iron casting, the overall bed has good rigidity and high precision. The surface of the guide rail has been treated with super-audio frequency quenching, which has high hardness and long service life. The carriage adopts the guide rail surface sticking plastic process, which has good wear resistance and high precision.

- Optional:CNC systems such as Siemens, FANUC, Guangshu and Kandi, fully enclosed protective covers, vertical and horizontal turrets.

- Standard configuration:

- Four-station electric knife holder, automatic centralized lubrication system, air-conditioning system, semi-closed protective cover.

SPECIFICATION Units QK1319 Swing over bed mm 630/800 Swing over cross slide mm 340/520 Distance between centers mm 1000 Pipe threading range mm 50-193 Guideway width mm 550 Max. load capacity T 3 Spindle bore mm 200 Spindle speed steps – VF. 2 steps Spindle speed range rpm 20-550 Chuck mm φ500 3-jaw manual Turret/tool post – CNC turret 4 position Tool shank size mm 32 x 32 X axis travel mm 320/420 Z axis travel mm 1000 X axis rapid traverse mm/min 4000 Z axis rapid traverse mm/min 6000 Tailstock quill diameter mm φ100 Tailstock quill taper – MT6 Tailstock quill travel mm 250 Main spindle motor kW 15 Coolant pump motor kW 0.125 Weight for 1500 kg 5100 Dimension for 1500 mm 4400x1900x2000