CNC vertical lathe VTC60

Product description of CNC vertical lathe:

VTC vertical CNC lathe is an excellent product designed and produced by our company after years of careful design based on the advanced technology of similar CNC vertical lathes at home and abroad. This series of CNC vertical lathes is economical and efficient, and is the preferred equipment for processing complex disc-shaped parts in the automotive, industrial and other mechanical industries. This series of CNC vertical lathes can process various short shafts and disc-shaped parts, and can turn various threads, arcs, and internal and external surfaces, end faces, and groove surfaces of rotating bodies. It is suitable for processing parts with large batches, high processing accuracy, and high dimensional consistency requirements. This series of CNC vertical lathes are widely used in the automotive industry at home and abroad. It is a high-quality, high-precision, low-cost, and high-efficiency CNC vertical lathe.

Description

CNC vertical lathe VTC60

Compared with previous similar CNC vertical lathes, it has the following advantages:

Important parameters such as the maximum processing diameter and two-axis rapid moving speed of CNC vertical lathes are close to or greater than similar foreign CNC vertical lathes.

The CNC vertical lathe has a compact structure, a reasonable layout of various functional components, and is easy to operate and maintain.

The CNC vertical lathe is inexpensive and extremely important. It is suitable for small and medium-sized enterprises to purchase single or batch, effectively reducing the procurement and operating costs of enterprises.

Main technical parameters of the product:

| item | VTC60 | |

| travel | x-axis | 450mm |

| z-axis | 650mm | |

| capacity | Maximum rotation diameter | φ650mm |

| Maximum turning diameter | φ600mm | |

| Spindle | Spindle speed | 100~1000r/min |

| Spindle motor power | 18.5kw | |

| Dimensions – External | 160mm | |

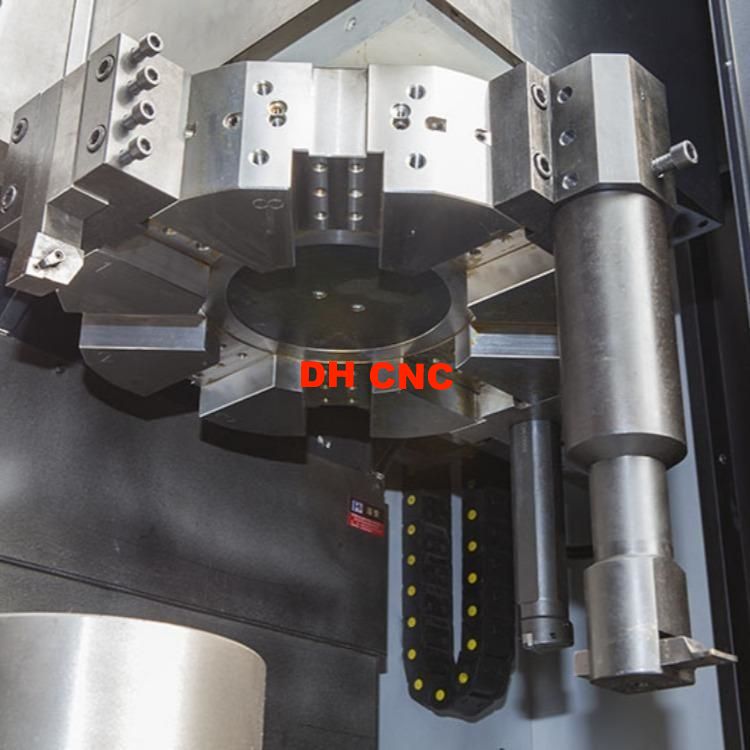

| Chuck and automatic tool changer | Chuck Type | Hydraulic chuck |

| Diameter chuck | φ500 | |

| workstation | Horizontal 8-station | |

| slide | X-axis slide | 2 pieces, 45 mm wide |

| Z-axis slide | 2 pieces, 55 mm wide | |

| Ball Screw | Ball screw accuracy | C3 |

| Ball screw diameter xyz | diameter:φ40 | |

| diameter:φ50 | ||

| guide | 10 mm | |

| Control System | Spindle motor | 18.5kw |

| X-axis motor | 18Nautical Mile | |

| Z-axis motor | 30Nautical Mile | |

| accuracy | Repeat positioning | 0.008mm |

| position | 0.008mm | |

| Minimum input increment | 0.001mm | |

| Requirements | Energy Source | 3¢-AC 380V 50Hz±10% |

| Other | Cross weight | 6500kg |

| Packing size | 2000*1950*3000mm | |