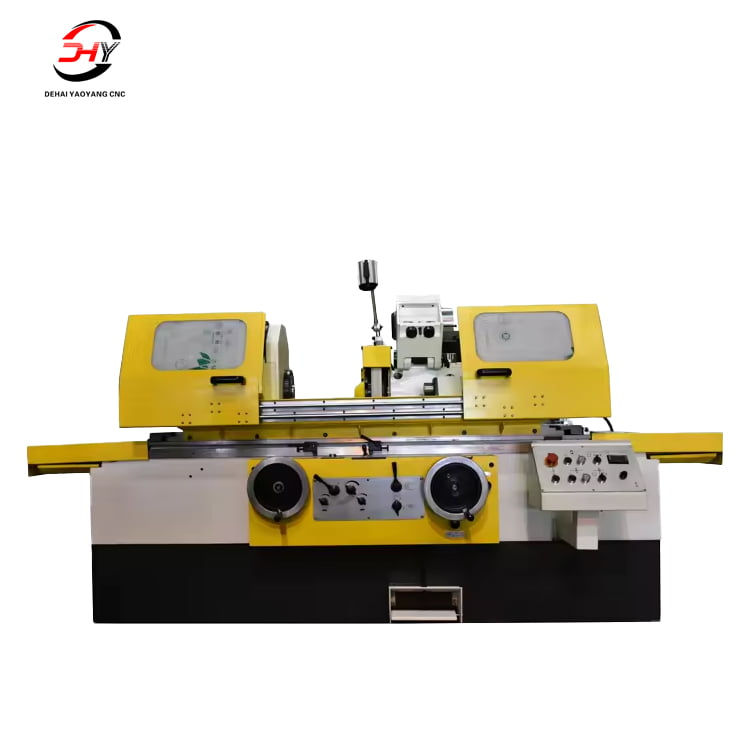

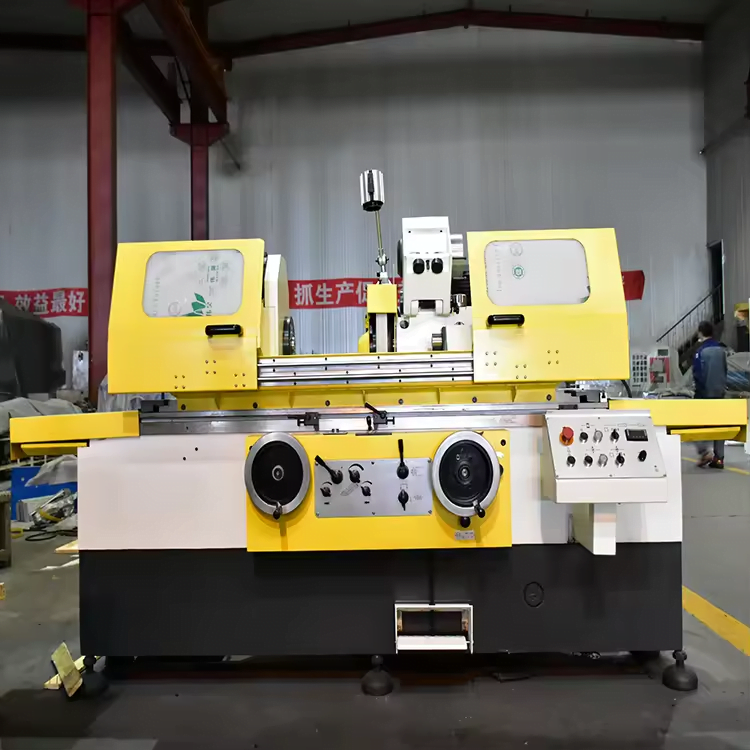

External cylindrical grinding machine MW1420

Characteristics of machine tools:

1. When conical grinding, the table can be swivelled to either side and exactly positioned by using the scale.

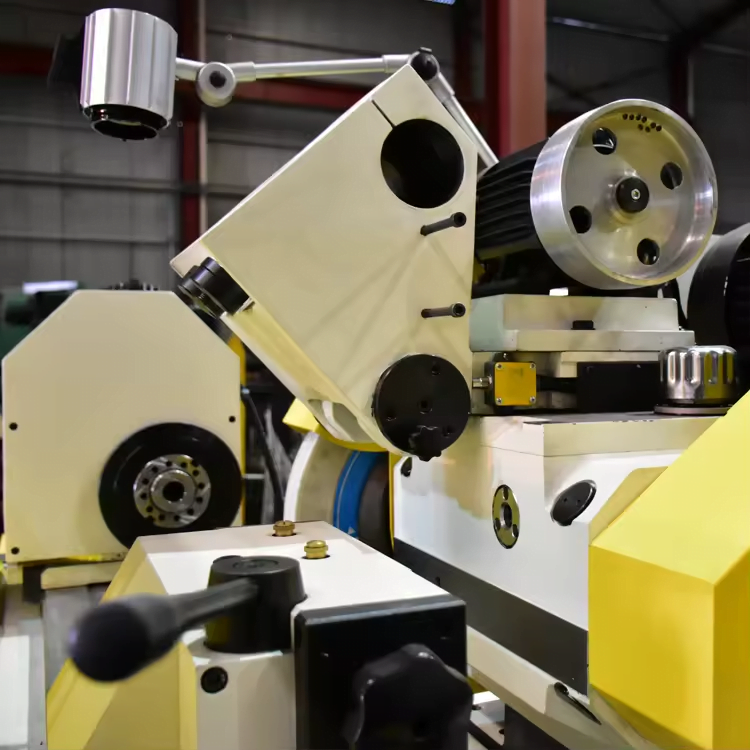

2. Oil film between bearing and spindle keeps vibrations ata minimum level, hence achieving outstanding results and top accuracy.

3. Precisely balanced spindle head and solid grinding head guarantee extraordinary results at any type of operation.

4. Strong reinforcements and solidly designed panels of the machine base makes it resistant to temperature fluctuations and deformations.

5. Spindle is mounted from both sides and features adjustable sliding bearings consisting of three segments.

6. Hydrodynamic bearing of spindle, therefore no contact between spindle and bearing.

7. Longitudinal table feed can be set to automatic mode -hydraulically driven or manual mode – by handwheel.

8. Stepless feed adjustments with the option of aprogrammable hold time at the end of each table movement.

9. Hydraulic or manual repositioning of grinding spindle stock.

10.Guideways in x- and y-axis are precisely constructed and hand-polished.

11.Longitudinal table guide and cross guide of grinding headstock each feature a V-guide and flat guide.

Description

External cylindrical grinding machine MW1420

Main performance characteristics: 1. The structure of the machine tool is reasonable, large machine tool bed weight, excellent stability, using the cross saddle structure, good rigidity, has the advantages of beautiful appearance and convenient operation. 2. Horizontal movement of working table (before and after) by servo motor drive, precision ball screw drive, to ensure accuracy,accurate positioning, in accordance with the procedures of automatic feeding, automatically and fast forward and rewind functions. 3. Working table vertical (or so) movement, the use of a V a flat guide, and the artificial precision shovel flowers, the use of hydraulic transmission, stable operation. 4. The grinding head up and down movement driven by a servo motor, which can achieve precise positioning accuracy, automatic feed and fast lifting function. 5. The Guangzhou CNC system GSK96 and two axis NC, according to the actual processing conditions free programming, with pulse wheel, X and Z axis feed can be free to switch freely. 6. Machine adopts full enclosed casing, can completely cover the whole of the working area, effectively prevent the splash of the cooling liquid and iron filings, and according to the requirements of clients connected ceiling spray dust removal device.

| Specification | unit | MW1420 | M1432B | M1450 | M1463 | |

| Distance between centers | mm | 500、750 | 1000、1500 | 1500、2000、3000 | 3000、4000、5000 | |

| Center height | mm | 135 | 180 | 270 | 335 | |

| Dia. Ground(O.D) | mm | 5~200 | 8~320 | 25~500 | 30~630 | |

| Dia. Ground(I.D) | mm | 25~100 | 30~100 | 30~200 | 30~200 | |

| Max. length ground(O.D) | mm | 500、750 | 1000、1500 | 1500、2000、3000 | 3000、4000、5000 | |

| Max. length ground(I.D) | mm | 100 | 125 | 320 | 320 | |

| Max. weight of work piece | kg | 100 | 150 | 1000 | 3000 | |

| Swiveling angle | ° | +90° | +90° | +90° | +90° | |

| Center taper(MT) | MT | 4 | 4 | 6 | metric80# | |

| Spindle speed | r/min | 50HZ:25~380 | 50HZ:25~220 | 50HZ:20~224 | 50HZ:8~150 | |

| Wheel spindle speed | rpm | 1670 | 1670 | 1330/665 | 740 | |

| Swiveling angle | ° | ±30° | ±30° | -30° | -30° | |

| wheel size Max. dimension of wheel(OD×W×ID) | mm | 400×50×203 | 400×50×203 | 500×75×305 | 900×75×305 | |

| Max. swivel angle | clockwise | ° | 3° | 3° | 3°(1500) 2°(2000、3000) | 2°(3000) 1°(4000、5000) |

| anticlockwise | ° | 7°(1000) 6° | 7°(1000) 6°(1500) | 6°(1500) 5°(2000)3°(3000) | 3°(3000)2°(4000、5000) | |

| Center tape(MT) | MT | 4 | 4 | 6 | metric80# | |

| Circularity | mm | 0.003 | 0.003 | 0.005 | 0.005 | |

| diameter consistency | mm | 0.005 | 0.005 | 0.008 | 0.008 | |

| Roughness | Ra | 0.2 | 0.2 | 0.32 | 0.32 | |

| Standard accessories: | ||||||

| Grinding wheel、Wheel balancing arbor、Wheel extractor、Wheel flange、Work lamp、Coolant tank、Center points | ||||||

| Optional accessories: | ||||||

| Wheel balancing stand、Coolant tank with magnetic separator、Coolant tank with magnetic separator and paper filter、End face wheel dresser、Radius wheel dresser、DRO、Online measuring attachment | ||||||