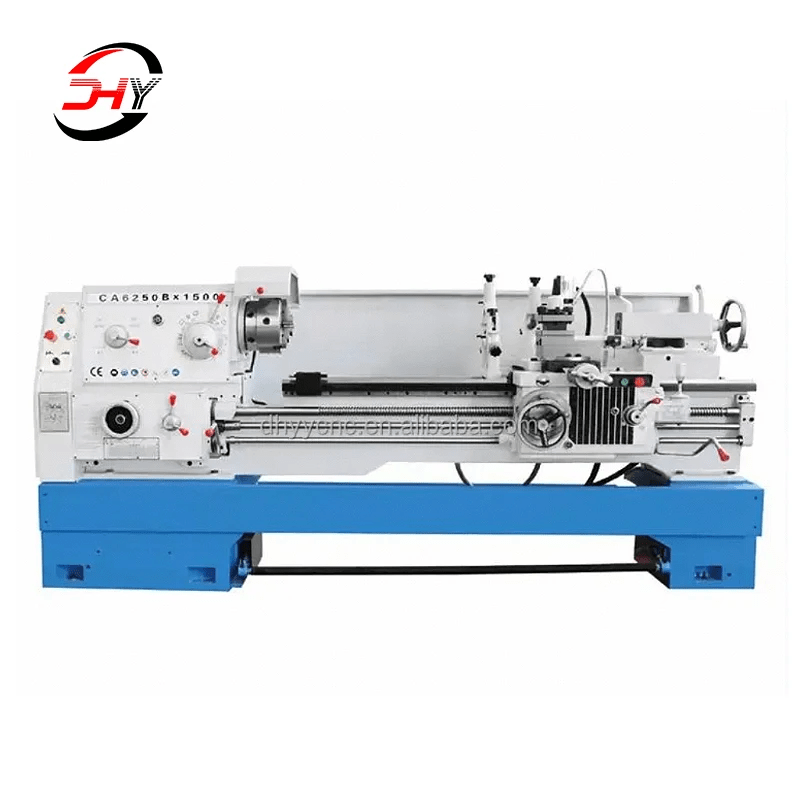

Manual lathe CA6150

◆The machine tool is inspected in strict accordance with the inspection procedures before leaving the factory, and a strong cutting test is done. The machine tool has good precision stability and processing reliability.

Description

Manual lathe CA6150

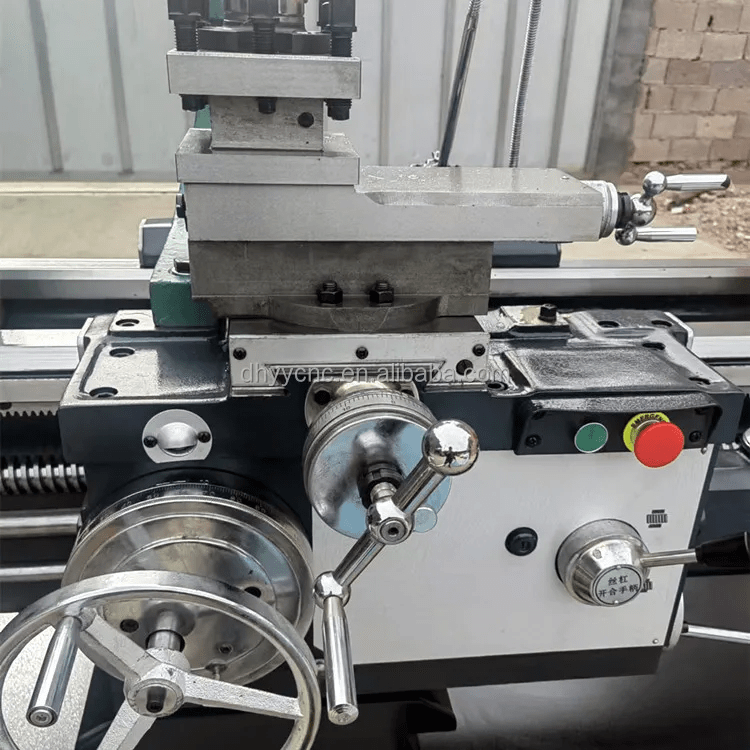

Feature : ◆This series of lathes is suitable for turning internal and external cylindrical surfaces, conical surfaces, and other rotating surfaces, turning various metric, inch, modulus, and diametral pitch threads, and can perform drilling and oil groove drawing work. ◆The bed of this series of lathes is wider than ordinary lathes, and the width of the guide rail is 400mm, which has high rigidity. The surface of the guide rail has been quenched by intermediate frequency, which is durable and wear-resistant. ◆The operation of the machine tool is flexible and centralized, and the sliding plate is equipped with a fast-moving mechanism. It adopts single-handle visual operation, which is pleasant. ◆The structural rigidity and transmission rigidity of the machine tool are higher than those of ordinary lathes, and the power utilization rate is high, which is suitable for strong cutting.

| Type | CA6140 CA6140B | CA6150 CA6150B CA6150C | CA6161 CA6161B CA6161C | CA6166 CA6166B CA6166C | CA6180 CA6180B CA6180C |

|---|---|---|---|---|---|

| CA6240 CA6240B | CA6250 CA6250B CA6250C | CA6261 CA6261B CA6261C | CA6266 CA6266B CA6266C | CA6280 CA6280B CA6280C | |

| Max. swing over bed | 400mm | 500mm | 610mm | 660mm | 800mm |

| Max. swing over carriage | 210mm | 300mm | 370mm | 400mm | 540mm |

| Max. swing in gap (CA62 series) | 630mm | 720mm | 830mm | 880mm | 1020mm |

| Max. effective length in gap (CA62 Series) | 210mm | ||||

| Max. length of workpiece | 750/1000/1500/2000/2200/3000/4000mm | ||||

| Width of bed | 400mm | ||||

| Section of turning tool | 25×25 mm | ||||

| Main spindle motor | 7.5kw(10HP) | ||||

| Spindle | |||||

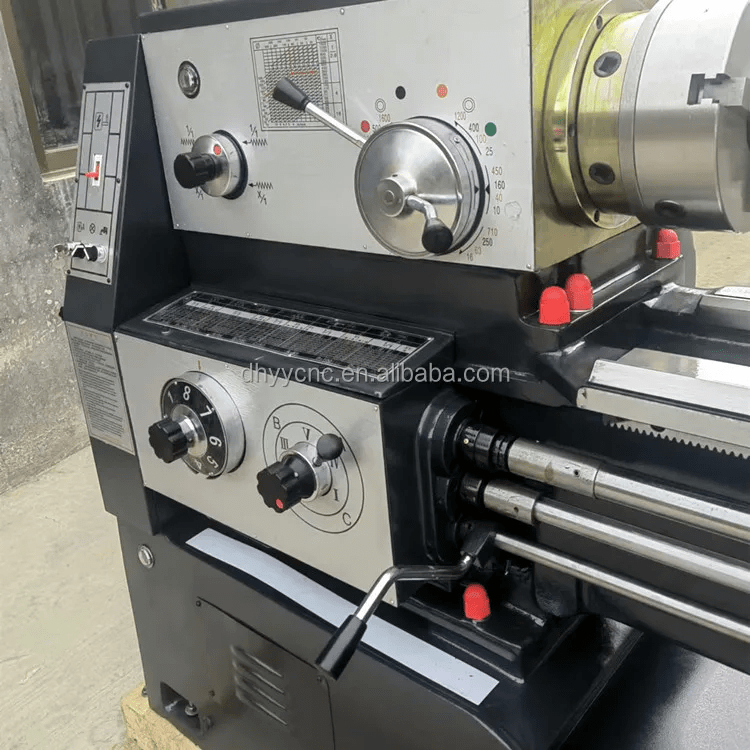

| Spindle speed | 16--1400rpm(24step) | ||||

| Spindle bore | 52mm (B:80mm),(C:105mm) | ||||

| Spindle taper | No.6(MT6)(Φ90 1:20)[Φ113:20] | ||||

| Feed | |||||

| NO. of feed | (64 kinds)(for each) | ||||

| Range of metric threads | (1-192mm) (44 kinds) | ||||

| Range of inch threads | (2-24tpi) (21kinds) | ||||

| Range of module threads | 0.25-48 (module 39 kinds) | ||||

| Range of diametral pitch threads | 1-96DP (37 kinds) | ||||

| Max. tailstock spindle travel | 150mm | ||||

| Tailstock spindle diameter | 75mm | ||||

| Taper of tailstock spindle centre hole | 1-96DP (37 kinds) | ||||

| Packing dimensions (L*W*H) | |||||

| Overall dimensions for 750mm | 2550×1140×1750mm | 2550×1140×1750mm | 2550×1140×1750mm | 2550×1140×1750mm | 2550×1140×1750mm |

| Overall dimensions for 1000mm | 2700×1140×1750mm | 2700×1140×1750mm | 2700×1140×1750mm | 2700×1140×1750mm | 2700×1140×1750mm |

| Overall dimensions for 1500mm | 3200×1140×1750mm | 3200×1140×1750mm | 3200×1140×1750mm | 3200×1140×1750mm | 3200×1140×1750mm |

| Overall dimensions for 2000mm | 3700×1140×1750mm | 3700×1140×1750mm | 3700×1140×1750mm | 3700×1140×1750mm | 3700×1140×1750mm |

| Overall dimensions for 2200mm | 4030×1140×1750mm | 4030×1140×1750mm | 4030×1140×1750mm | 4030×1140×1750mm | 4030×1140×1750mm |

| Overall dimensions for 3000mm | 4850×1140×1750mm | 4850×1140×1750mm | 4850×1140×1750mm | 4850×1140×1750mm | 4850×1140×1750mm |

| Overall dimensions for 4000mm | 5800×1140×1750mm | 5800×1140×1750mm | 5800×1140×1750mm | 5800×1140×1750mm | 5800×1140×1750mm |

| Weight (kg) | |||||

| Overall dimensions for 750mm | 2100 /1990 | 2170/2060 | 2300/2180 | 2380/2260 | 2520/2400 |

| Overall dimensions for 1000mm | 2190/2070 | 2260/2140 | 2380/2250 | 2570/2450 | 2720/2560 |

| Overall dimensions for 1500mm | 2350/2220 | 2450/2290 | 2577/2437 | 2810/2640 | 2980/2800 |

| Overall dimensions for 2000mm | 2720/2570 | 2800/2640 | 2940/2787 | 3050/2880 | 3260/3087 |

| Overall dimensions for 2200mm | 2800/2600 | 3940/2790 | 3120/2970 | 3390/3180 | 3490/3287 |

| Overall dimensions for 3000mm | 3300/3200 | 3450/3300 | 3600/3450 | 3930/3687 | 4200/3887 |

| Overall dimensions for 4000mm | 3500/3400 | 3750/3600 | 3950/3800 | 4580/4200 | 4850/4500 |

| Features: | |||||

| 1. This series lathe machine is suitable for intemal and extemal turning,tapering,and other rotating faces, metric, module and inch threads,as well as drilling and pull oil slot. | |||||

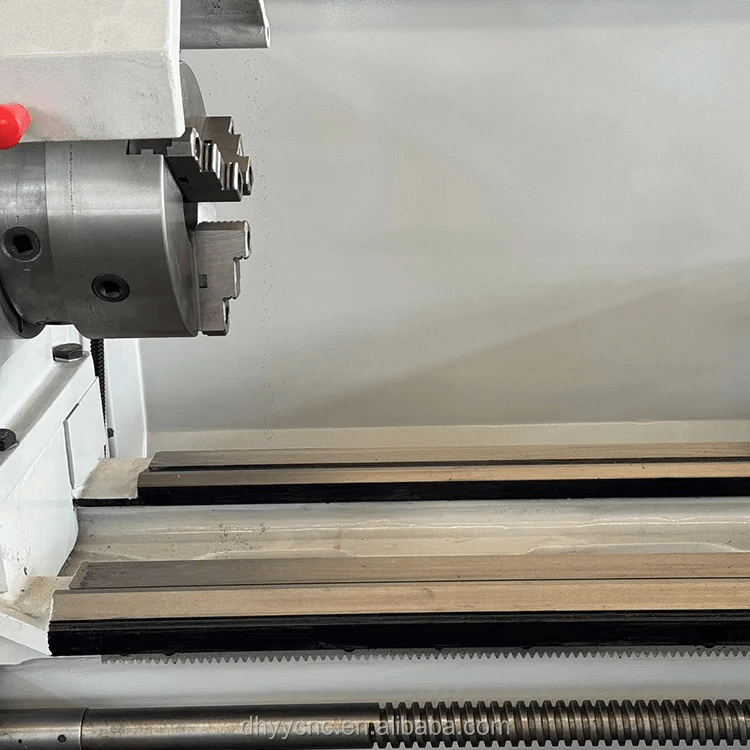

| 2. The lathe bed is 400mm,with high hardness on guideway,the guideway is through | |||||

| 3. This machine is easy to operate,with rapid device for carriage,design with single hand wheel to operate. high-frequency quenching, wear-resisting. | |||||

| 4. The strength and rigidity of machine is higher than normal lathe machine,high efficiency,suitable for heavy duty machining. | |||||