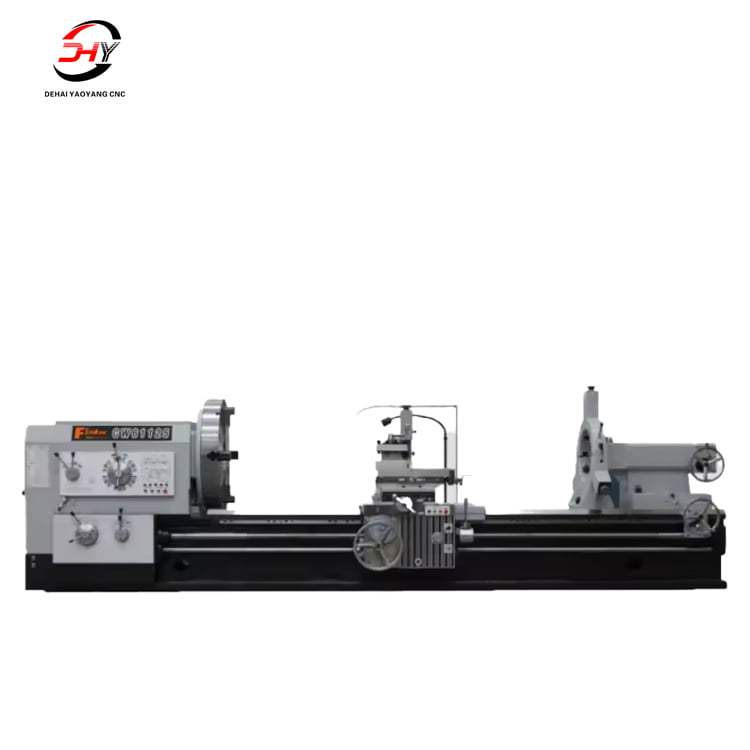

Manual lathe CW61125

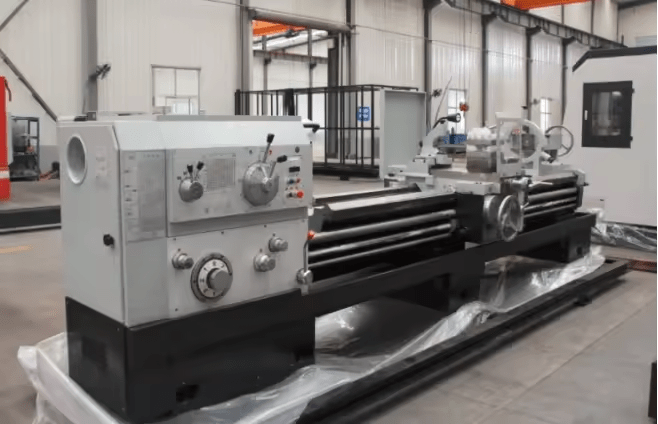

◆The machine tool is inspected in strict accordance with the inspection procedures before leaving the factory,and a strong cutting test is done. The machine tool has good precision stability and processing reliability

Description

Manual lathe CW61125

Feature :

◆The CW61125 lathe has high power, strong rigidity, and a wide range of spindle speed regulation, suitable for strong or high-speed cutting. It can turn end faces, outer circles, flesh holes, as well as various threads in metric, inch, module, and diameter pitch. It can also undertake drilling, nesting, boring and other processes.

◆The bed of this series of lathes is wider than ordinary lathes, and the width of the guide rail is 600/755mm,

which has high rigidity. The surface of the guide rail has been quenched by intermediate frequency, which is durable and

wear-resistant.

which has high rigidity. The surface of the guide rail has been quenched by intermediate frequency, which is durable and

wear-resistant.

◆The operation of the machine tool is flexible and centralized, and the sliding plate is equipped with a

fast-moving mechanism. It adopts single-handle visual operation, which is pleasant.

fast-moving mechanism. It adopts single-handle visual operation, which is pleasant.

◆The structural rigidity and transmission rigidity of the machine tool are higher than those of ordinary lathes, and the power utilization rate is high, which is suitable for strong cutting.

| Specification | UNIT | CW61100 | CW61125B | CW61140B |

|---|---|---|---|---|

| Swing ove bed | mm | 1000 | 1250 | 1400 |

| Swingovwr cross slide | mm | 610 | 850 | 1000 |

| Distance between centers | mm | 1500/3000 | 1500/3000 | 1500/3000 |

| Guideway width | mm | 755 | 755 | 755 |

| Max.load capacity | T | 6 | 6 | 6 |

| Spindle bore | mm | 130 | 130 | 130 |

| Spindle bore taper | — | Metric φ140/MT6 | Metric φ140/MT6 | Metric φ140/MT6 |

| Spindle nose type | — | A2-15 | A2-15 | A2-15 |

| Spindle spesd steps | — | FWD.21 steps | FWD.21 steps | FWD.21 steps |

| Spindle speed range | rpm | 3.15-315 | 3.15-315 | 3.15-315 |

| Chuck | mm | 1000 4-jaw manual | 1000 4-jaw manual | 1000 4-jaw manual |

| Turret/tool post | — | Manual turret 4 position | Manual turret 4 position | Manual turret 4 position |

| Tool shank size | mm | 45×45 | 45×45 | 45×45 |

| Y axis travel | mm | 520 | 620 | 620 |

| Z axis travel | mm | 1350/2850 | 1350/2850 | 1350/2850 |

| X axis feed grade/range | mm/r | 56/0.05-6 | 56/0.05-6 | 56/0.05-6 |

| Z axis feed grade/range | mm/r | 56/0.1-12 | 56/0.1-12 | 56/0.1-12 |

| X axis rapid traverse | mm/min | 1870 | 1870 | 1870 |

| Z axis rapid traverse | mm/min | 3740 | 3740 | 3740 |

| Metric thread grade/range | mm | 44/1-120 | 44/1-120 | 44/1-120 |

| Inch thread grade/range | T.P.I | 31/28-3/8 | 31/28-3/8 | 31/28-3/8 |

| Module thread grade/range | mm | 45/0.5-60 | 45/0.5-60 | 45/0.5-60 |

| DP thread grade/range | D.P. | 30/56-1 | 30/56-1 | 30/56-1 |

| Teilstock quill diameter | mm | φ140 | φ140 | φ140 |

| Tailstosk quill taper | mm | MT6 | MT6 | MT6 |

| Tailstock quill travel | mm | 300 | 300 | 300 |

| Main sindle motor | kW | 22 | 22 | 22 |

| Rapid traverse motor | kW | 1.5 | 1.5 | 1.5 |

| Coolant pump motor | kW | 0.125 | 0.125 | 0.125 |

| Width x Height | mm | 2000×1800 | 2000×1950 | 2250×2050 |

| Length | mm | 4600/6100 | 4600/6100 | 4600/6100 |

| Net weight | T | 9.6/107 | 10.6/11.7 | 11.2/12.3 |