Slant bed lathe TCK36

The bed adopts a high-rigidity 45° inclined-back integral bed, which is convenient for chip removal. It is equipped with a separate water tank to completely prevent leakage and is easy to maintain.

Description

Slant bed lathe TCK36

1. Machine tool structure TCK series multi-functional CNC bed, the bed is made of box structure and tough cast iron (HT-300), cast with integral molding casting technology, and processed by high-precision machining center in one clamping. Therefore, it has the characteristics of strong overall rigidity, good accuracy retention of machine tools, and high reliability in use.

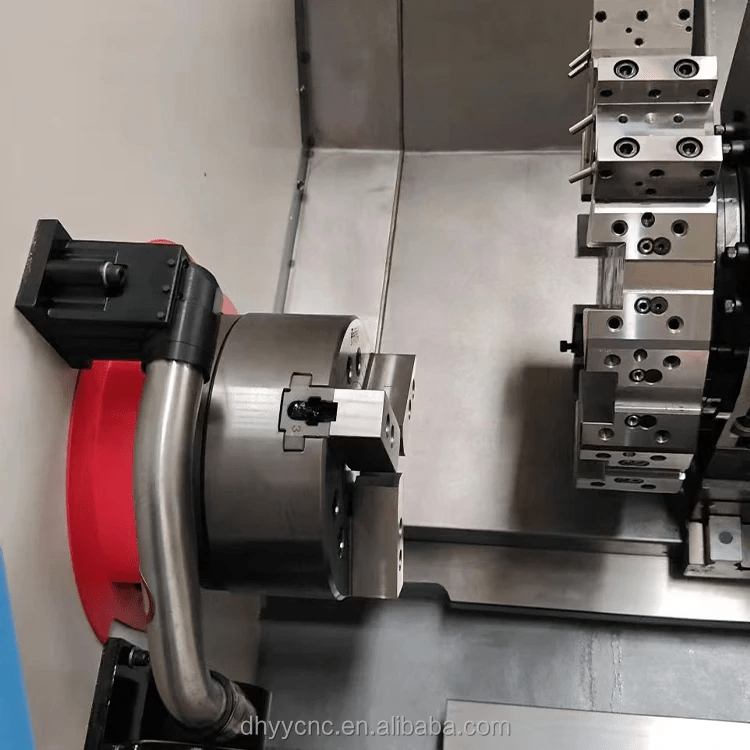

2. Tool holder TCK series multifunctional CNC lathe adopts 8-station hydraulic tool holder, and the tool holder can be interchanged at each position of the tool table. Optional 12-station hydraulic servo turret and live tool turret.

| SPECIFICATIONS | Units | TCK36 | TCK46 | TCK56 |

|---|---|---|---|---|

| Swing over bed | mm | 400 | 460 | 560 |

| Swing over cross slide | mm | 200 | 260 | 310 |

| Distance between centers | mm | 500 | 500/1000/1500 | 750/1000/1500 |

| Guideway width | ° | 45 | 45 | 45 |

| Spindle bore | mm | 56 | 56 | 62 |

| Spindle speed steps | - | Stepless | Stepless | Stepless |

| Spindle speed range | rpm | 35-4500 | 35-4500 | 35-4500 |

| Spindle type | A2-5 | A2-5 | A2-6 | |

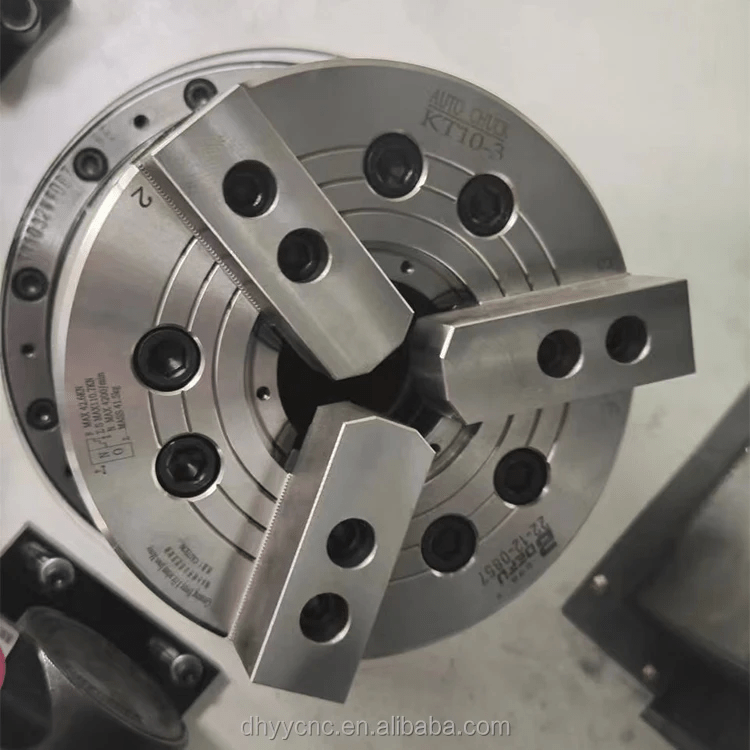

| Chuck | in | 8in Hydraulic chuck | 8in Hydraulic chuck | 10in Hydraulic chuck |

| Turret/tool post | - | Gang type Tool Holder | Hydraulic turret 8position | Hydraulic turret 8position |

| Tool shank size | mm | 20x20 | 25 x 25 | 25x25 |

| Boring tool holder size | mm | φ40 | φ40 | φ50 |

| X axis travel | mm | 200 | 200 | 260 |

| Z axis travel | mm | 500 | 500/1000/1500 | 750/1000/1500 |

| X axis rapid traverse | mm/min | 10000 | 10000 | 10000 |

| Z axis rapid traverse | mm/min | 15000 | 15000 | 15000 |

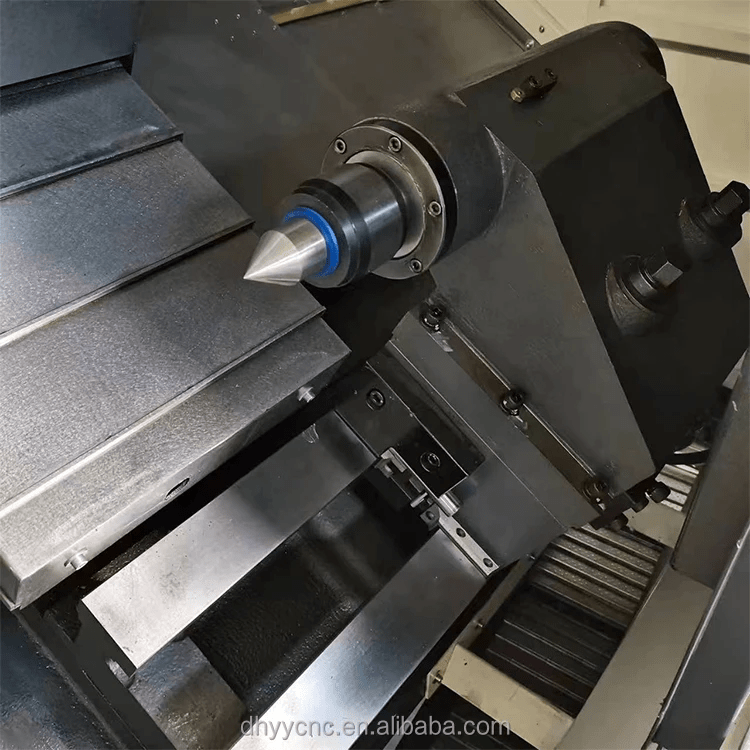

| Tailstock quill diameter | mm | φ75 | φ75 | φ130 |

| positioning accuracy | mm | 0.005 | 0.005 | 0.005 |

| Repeatability | 0.008 | 0.008 | 0.01 | |

| Tailstock quill taper | - | MT4 | MT4 | MT4 |

| Tailstock quill travel | mm | 150 | 150 | 150 |

| Main spindle motor | kw | 7.5 | 7.5 | 11 |

| Coolant pump motor | kw | 0.37 | 0.37 | 0.37 |

| Weight for 500 | kg | 2400 | 2500 | 3900 |

| Weight for 1000 | kg | 3100 | 3300 | 4500 |

| Weight for 1500 | kg | 4300 | 4500 | 5000 |

| Dimension for 500 | mm | 2650*1700*1550 | 2800*1800*1600 | 3100*2000*2000 |

| Dimension for 1000 | mm | 3150*1700*1550 | 3300*1800*1600 | 3500x2050x2300 |

| Dimension for 1500 | mm | 3800*1700*1550 | 3900*1800*1600 | 4300x2050x2300 |