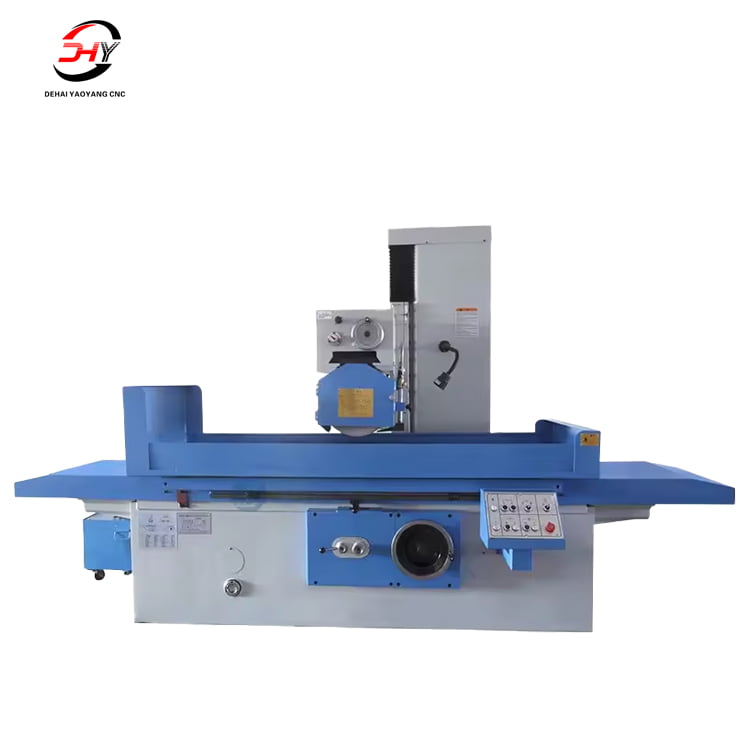

Surface grinding machine M7132

Application:

Applicable to all kinds of processing machinery, auto parts, fixture, magnetic steel, mould parts processing industry.

The machine tool can be made of grinding steel, iron, ceramics and non-ferrous metal parts.

Description

Surface grinding machine M7132

Specification

The main performance characteristics:

The screw rod of the machine tool is made of special alloy steel through strict processing and heat treatment technology.

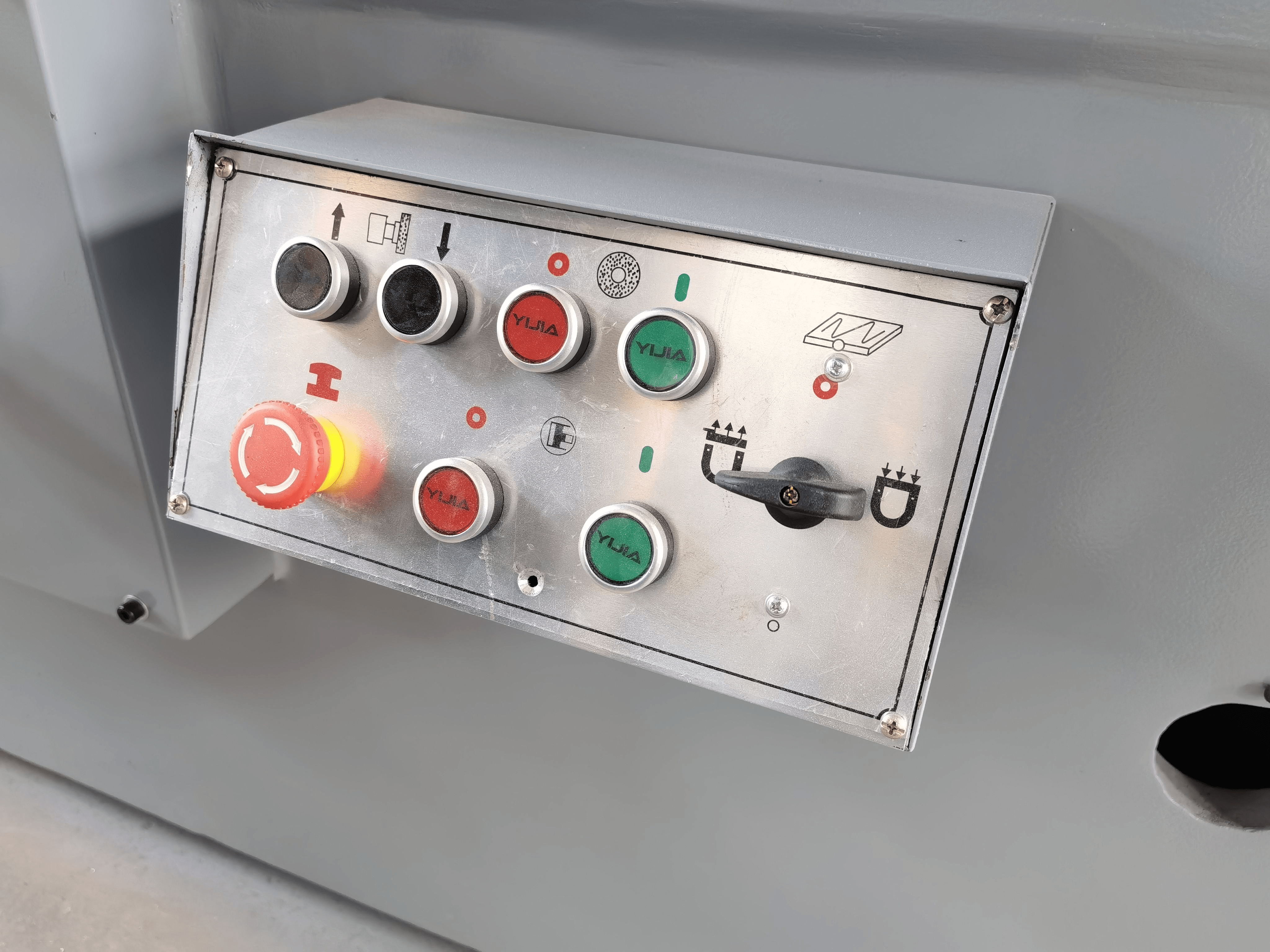

Grinding head vertical rapid lifting, improve production efficiency.

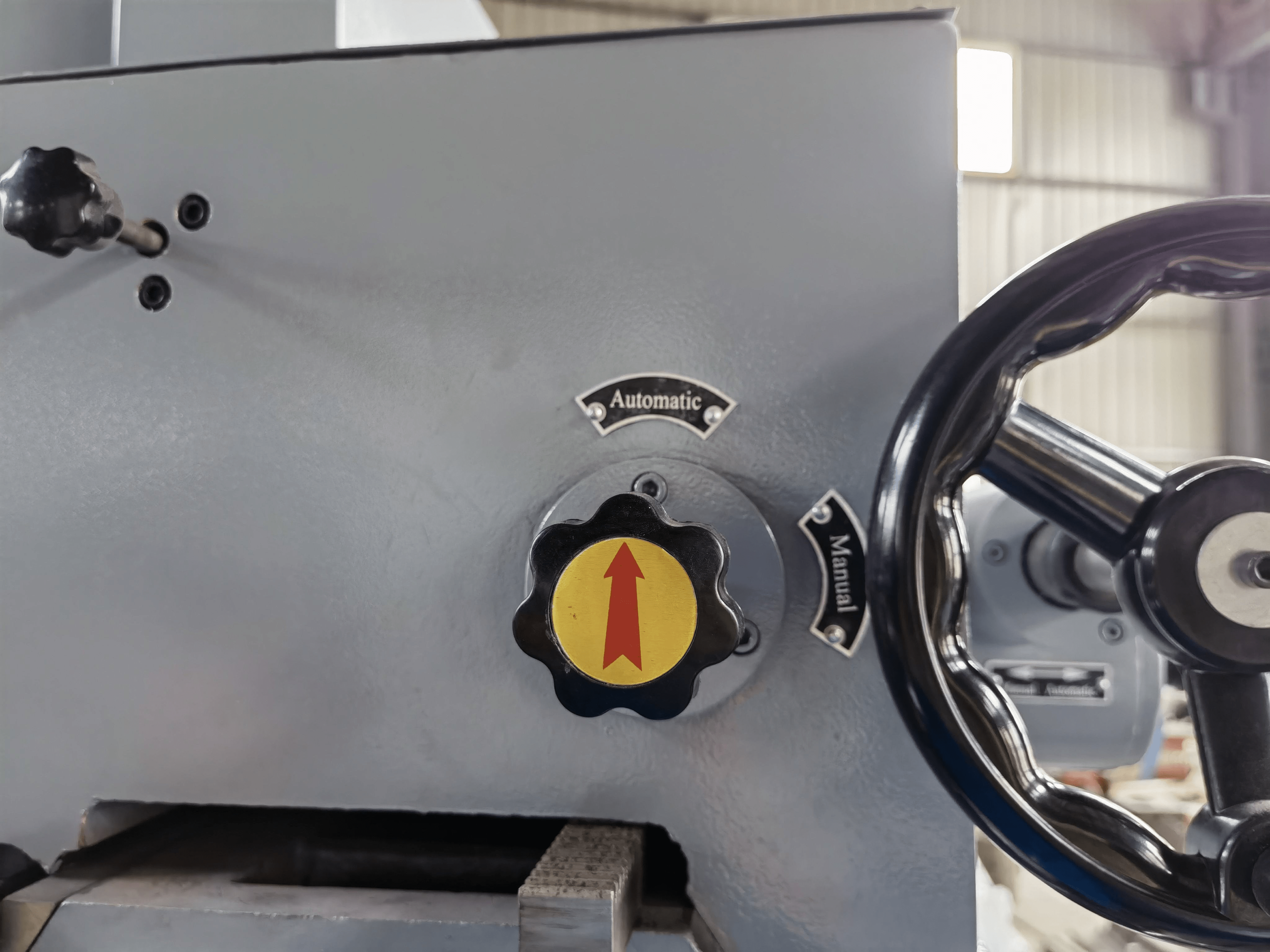

The grinding head lateral movement driven by hydraulic motor, which can also be manually.

The lifting mechanism and the triangle bracket adopt eccentric design, which is easy to adjust, and greatly prolong the service

life of the machine tool.

| model | unit | M7132-1000 | M7132-1600 | M7132-2000 | M7140-1000 | M7140-1600 | M7140-2000 | |

| Workbench | Table size (length×width) | mm | 1000×320 | 1600×320 | 2000×320 | 1000×400 | 1600×400 | 2000×400 |

| Max. longitudinal stroke of worktable | mm | 1100 | 1700 | 2100 | 1100 | 1700 | 2100 | |

| T-slot of worktable number of slots×width of slot | 3×18 | 3×18 | 3×18 | 3×18 | 3×18 | 3×18 | ||

| Table speed (infinite) | m/min | 3--25 | 3--25 | 3--25 | 3--25 | 3--25 | 3--25 | |

| Grinding head | Max. distance from the center of the grinding wheel shaft to the worktable | mm | 570 | 570 | 570 | 575 | 575 | 575 |

| Max. stroke of grinding head Horizontal (manual and hydraulic) | mm | 350 | 350 | 350 | 440 | 440 | 440 | |

| Max. stroke of grinding head Vertical (manual) | mm | 400 | 400 | 400 | 400 | 400 | 400 | |

| Rotating Speed of Grinding Wheel Shaft | rpm | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | |

| Grinding wheel size (outer diameter×width×inner diameter) | mm | 350×40×127 | 350×40×127 | |||||

| Vertical feed handwheel dial value | mm | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |

| Grinding head feed per turn of handwheel | mm | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | |

| Total motor power | kw | 11 | 12 | 12 | 11 | 12 | 12 | |

| Grinding head motor | power | kw | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

| Rotating speed | r/min | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | |

| Fast lifting motor | power | kw | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.55 |

| Rotating speed | r/min | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | |

| Oil pump motor | Oil pump motor | kw | 3 | 4 | 4 | 3 | 4 | 4 |

| Rotating speed | r/min | 960 | 960 | 960 | 960 | 960 | 960 | |

| Cooling pump motor | Cooling pump motor | kw | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 |

| Rotating speed | r/min | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | |

| Oil pump | flow | L/min | 100 | 125 | 125 | 100 | 100 | 125/50 |

| Work pressure | MPa | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Working accuracy | Parallelism of the machined surface to the base surface | mm | 1000:0.015 | 1000:0.015 | 1000:0.015 | 1000:0.015 | 1000:0.015 | 1000:0.015 |

| Surface roughness | μm | Ra0.63 | Ra0.63 | Ra0.63 | Ra0.63 | Ra0.63 | Ra0.63 | |

| Machine weight | net weight/Gross weight | kg | 3700/4300 | 4300/4900 | 4830/5300 | 3800/4200 | 5300/6000 | 6300/7000 |

| Overall dimensions (length x width x height) | mm | 2700×1700×2100 | 4400×1700×2100 | 5400×1700×2300 | 2700×1750×2100 | 4400×1750×2100 | 5400×1750×2100 | |

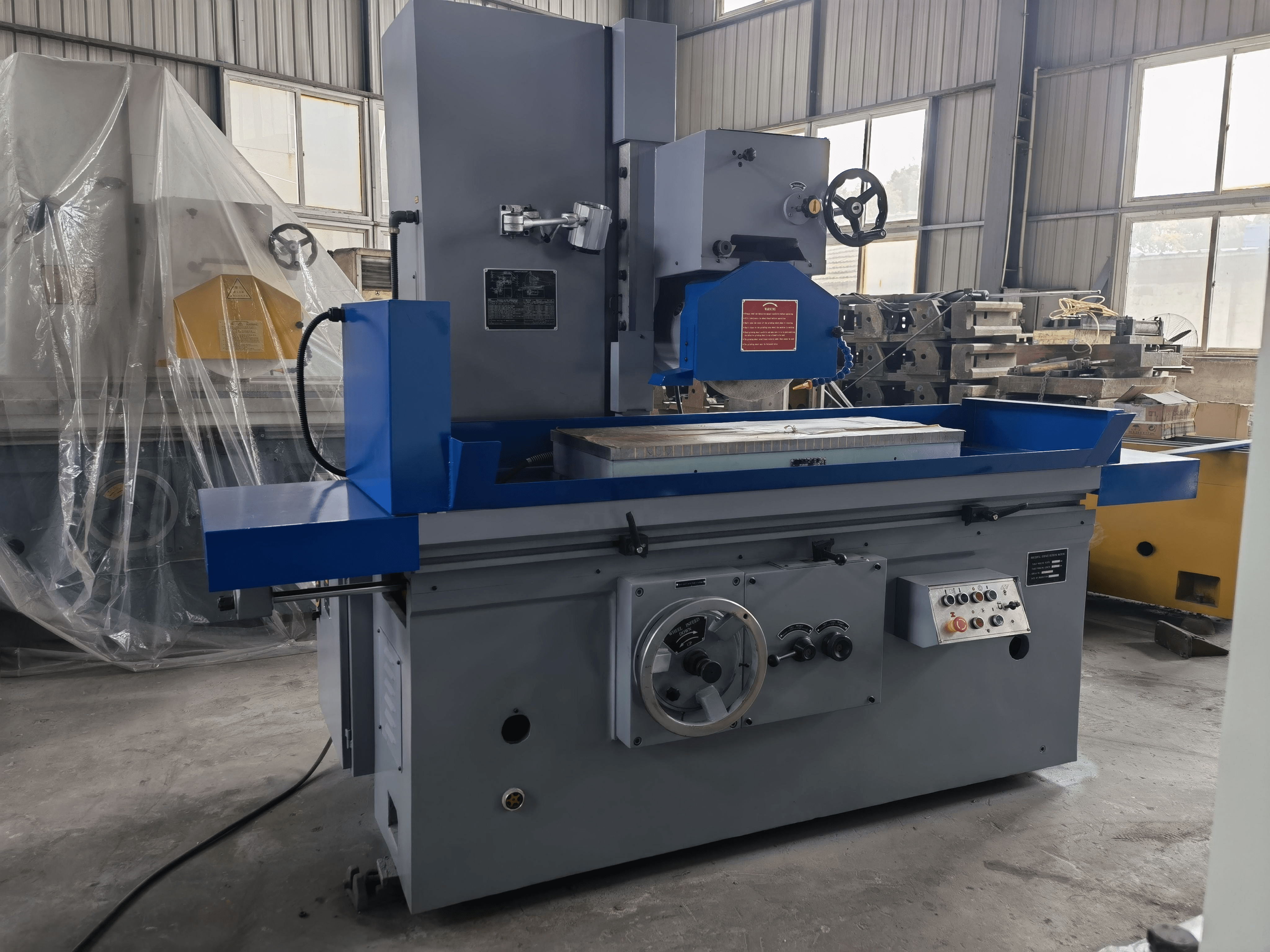

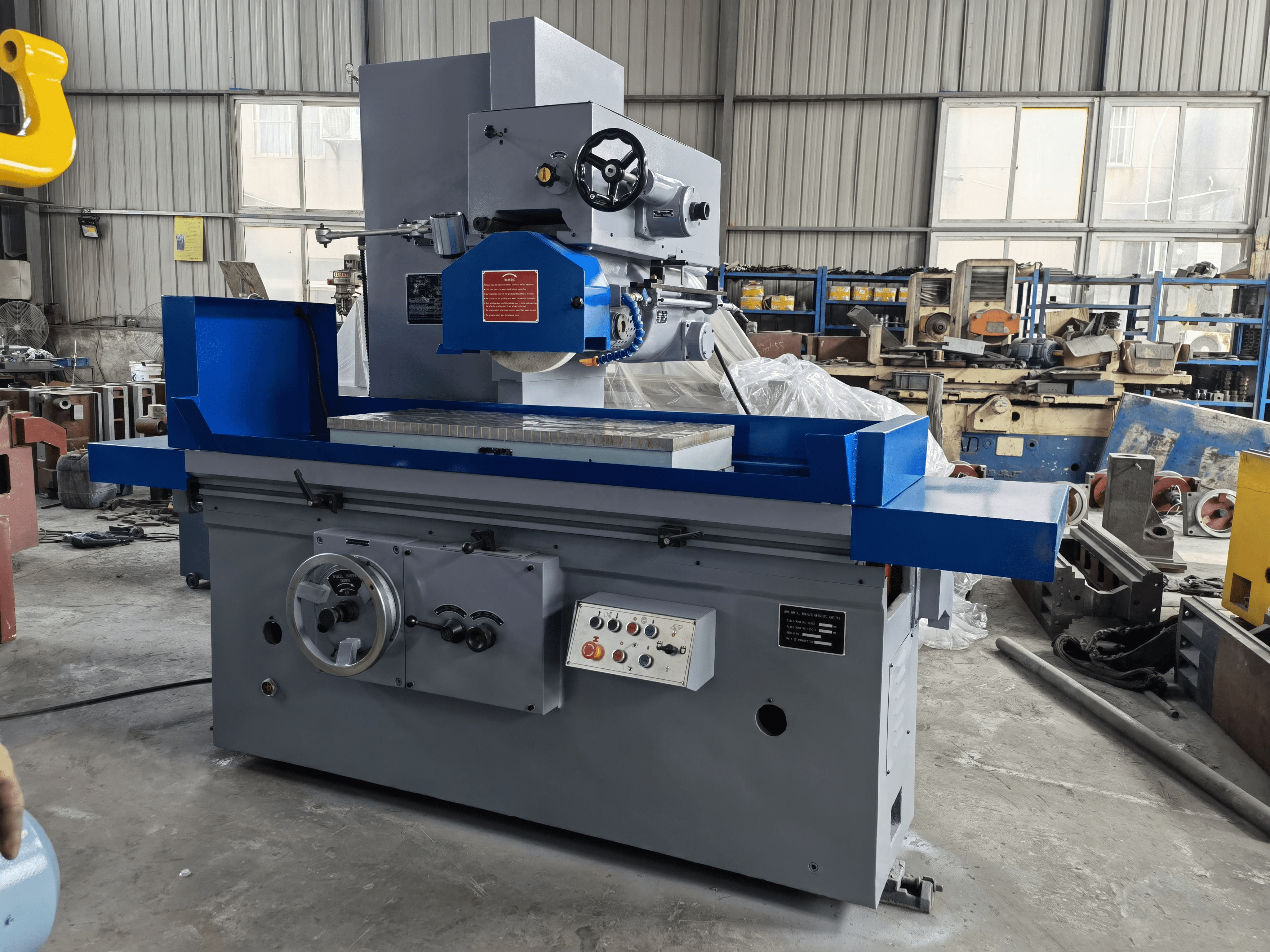

| This series of machine tools is mainly a machine tool that grinds the surface of the workpiece around the grinding wheel. It can also grind squares, grooves, molds, etc., and has a wide range of applications.It is suitable for all kinds of machinery processing plants, automobile, mold, industry and other parts processing plants. This machine tool can grind parts made of steel, iron, and non-ferrous metals. | ||||||||

| 1. The machine adopts a left-mounted column, a side-mounted pallet/grinding head layout, and the use of mature grinding head mobile product technology, so that the product has a good structural rigidity. | ||||||||

| 2. The grinding head adopts a bearing-type grinding head and is driven by a 7.5KW motor to ensure good cutting results | ||||||||

| 3. The worktable moves longitudinally (left and right), adopts a V and a flat guide rail, and is manually precision scraped. The hydraulic system adopts an advanced oil pump motor and an integrated hydraulic control unit, which has high precision and is convenient to use and maintain. The worktable moves longitudinally and is driven by the right vane pump, with stable movement and low noise. The oil pool is equipped with a cooling device, with low temperature rise and small thermal deformation. | ||||||||

| 4. The grinding head moves up and down and adopts a worm gear structure to reduce the sliding caused by the weight of the large grinding head. When the screw is running up and down, the grinding head feeds smoothly and protects the screw. | ||||||||