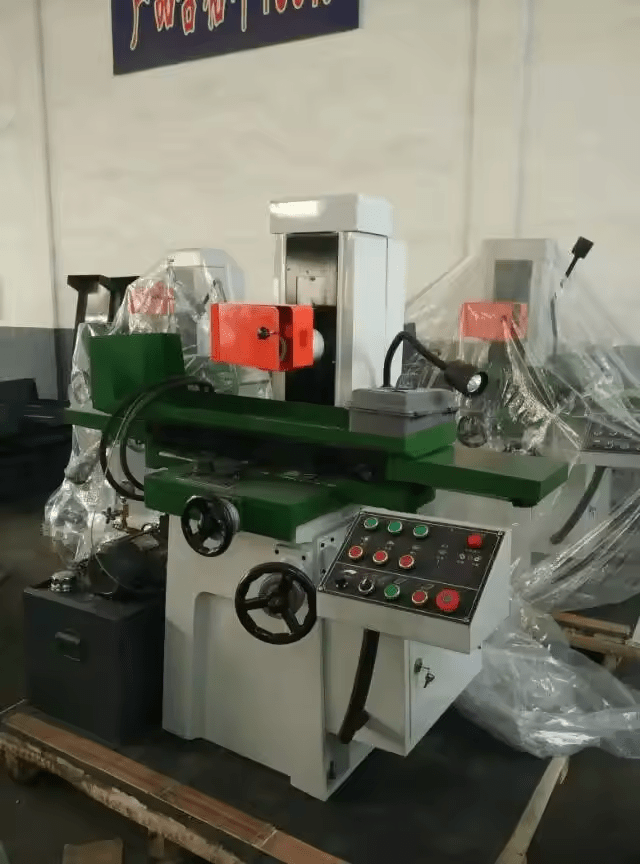

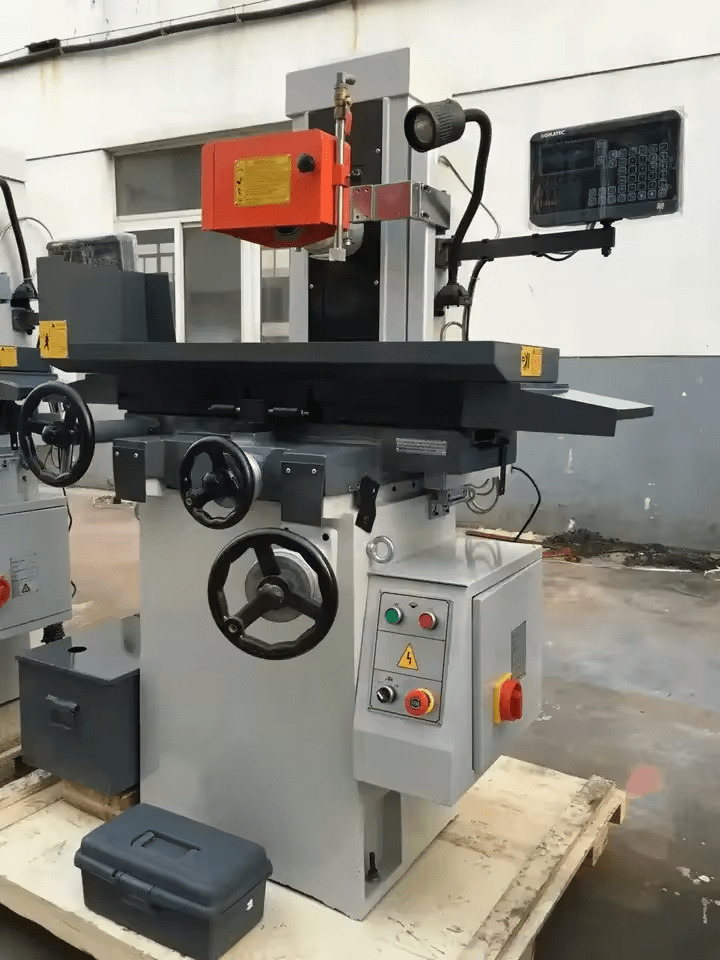

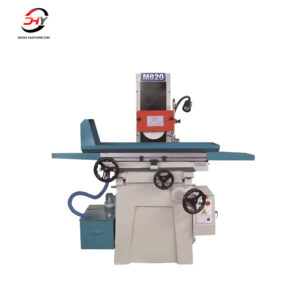

Surface grinding machine MY820

Application:

Applicable to all kinds of processing machinery, auto parts, fixture, magnetic steel, mould parts processing industry.

The machine tool can be made of grinding steel, iron, ceramics and non-ferrous metal parts.

Description

Surface grinding machine MY820

The main performance characteristics:

1. The structure of the machine tool is reasonable, large machine tool bed weight, excellent stability, using the cross saddle structure, good rigidity, has the advantages of beautiful appearance and convenient operation.

2. Horizontal movement of working table (before and after) by servo motor drive, precision ball screw drive, to ensure accuracy, accurate positioning, in accordance with the procedures of automatic feeding, automatically and fast forward and rewind functions.

3. Working table vertical (or so) movement, the use of a V a flat guide, and the artificial precision shovel flowers, the use of

hydraulic transmission, stable operation.

4. The grinding head up and down movement driven by a servo motor, which can achieve precise positioning accuracy, automatic feed and fast lifting function.

5. The Guangzhou CNC system GSK96 and two axis NC, according to the actual processing conditions free programming, with pulse wheel, X and Z axis feed can be free to switch freely.

6. Machine adopts full enclosed casing, can completely cover the whole of the working area, effectively prevent the splash of the cooling liquid and iron filings, and according to the requirements of clients connected ceiling spray dust removal device. (optional)

7. The characteristics of the CNC grinding machine is realize three-axis full automation, the second axis plane grinder while reducing the labor intensity of the operator, but also a single stand-alone operation, three axis automatic surface grinder, a worker can be 3 – 5 machines are operating at the same time, greatly reduce the labor cost, especially when the batch processing,the benefit is more remarkable.

| Model | unit | MY618 | MY820 | MY1022 | MY1224 | MY1230 | MY1232 | ||

| Bench | Worktable size(L×W×) | m | 460×180 | 480×200 | 540×250 | 600×300 | 700×300 | 800×320 | |

| Max. travel of table (L×W) | m | 500×190 | 530×220 | 560×260 | 630×320 | 760×370 | 860×380 | ||

| Table Max. cutting area (L×W) | m | 500×190 | 530×220 | 560×260 | 630×320 | 760×370 | 860×380 | ||

| Number of T-Slot | mm | 1×12 | 1×14 | 1×14 | 1×14 | 1×14 | 1×14 | ||

| The grinding head | Distance From Table Surface To Spindle Center | mm | 450 | 450 | 450 | 490 | 540 | 540 | |

| Wheel Size(dia×width×bore) | mm | 200×20×31.75 | 200×20×31.75 | 200×20×31.75 | 300×30×75 | 300×30×75 | 335×30×127 | ||

| Spindle speeds | r/m | 335 | 2850 | 2850 | 1440 | 1440 | 1440 | ||

| The amount of feed | Table longitudinal (left and right)speed (stepless) | m/min | 3-23 | 3-20 | 3-20 | 3-20 | 5-25 | 5-25 | |

| Table horizontal (before and after)the amount of feed | Continuous (variable speed) | mm/min | 150 | 150 | 150 | 150 | 150 | 150 | |

| Intermittent (stepless) | mm/ | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | ||

| The handwheel rotates | mm | 2.5 | 2.5 | 4 | 4 | 4 | 4 | ||

| Hand wheel each grid | mm | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | ||

| Vertical(up and down)feed wheel feed | The handwheel rotates | mm | 1.25 | 1.25 | 2 | 2 | 2 | 2 | |

| Hand wheel each grid | mm | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | ||

| Motor power | Spindle motor | kw | 1.5 | 1.5 | 1.5 | 4 | 4 | 4 | |

| Cooling motor | w | 40 | 40 | 40 | 40 | 40 | 40 | ||

| Hydraulic system | Hydraulic motor | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Working Pressure | Mpa | 3 | 3 | 3 | 3 | 3 | 3 | ||

| Oil tank capacity | L | 80 | 80 | 80 | 80 | 80 | 80 | ||

| Max. Capacity | L/min | 18 | 18 | 18 | 18 | 18 | 18 | ||

| Working precision | The machined surface of the base of parallelism | mm | 300/0.005 | 300/0.004 | 300/0.004 | 300/0.004 | 300/0.004 | 300/0.004 | |

| Surface Roughess | μm | Ra0.32 | Ra0.32 | Ra0.32 | Ra0.32 | Ra0.32 | Ra0.32 | ||

| Weighe of machine | Net | T | 0.81 | 1.05 | 1.25 | 1.5 | 2.1 | 2.5 | |

| Cross | T | 0.85 | 1.15 | 1.35 | 1.65 | 2.35 | 2.75 | ||

| Packing size (L×W×H) | mm | 1700×1250×1900 | 1700×1300×1920 | 1750×1350×1960 | 1950×1700×2030 | 1950×1700×2030 | 2000×1800×2030 | ||

| Characteristics of machine tools: | |||||||||

| 1.The machine is reasonable in structure, good rigidity, beautiful appearance,convenient operation. | |||||||||

| 2.Using precision plastic guide surface and precision scraping, grinding imported hydraulic transmission, drive by synchronous. | |||||||||

| 3.The main mechanical valve is a special valve grinder, is divided into two parts,the mechanical commutation control, throttle control. Throttle control part and unloading function, can realize the station start and stop. | |||||||||

| 4.Grinding can be all kinds of plane and complex shaped surface, suitable for motor without grinding the feed, according to user needs with a permanent magnet sucker or electromagnetic sucker. | |||||||||